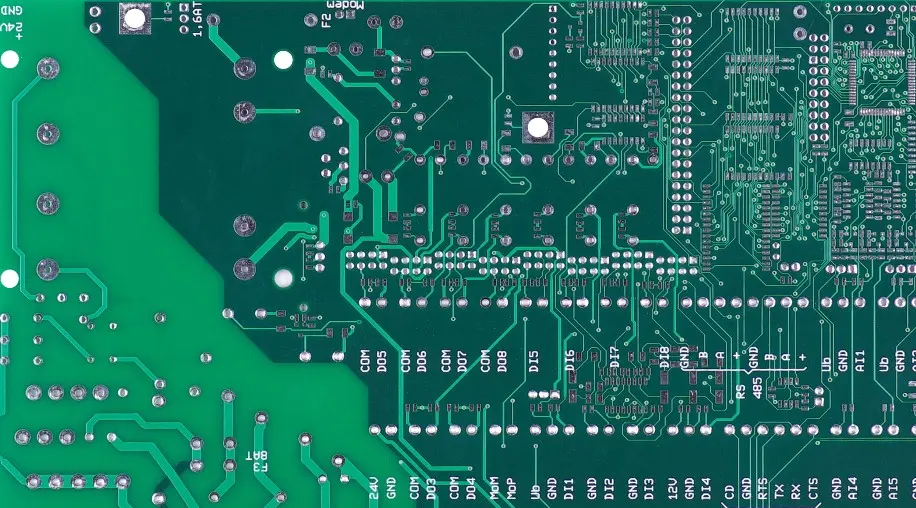

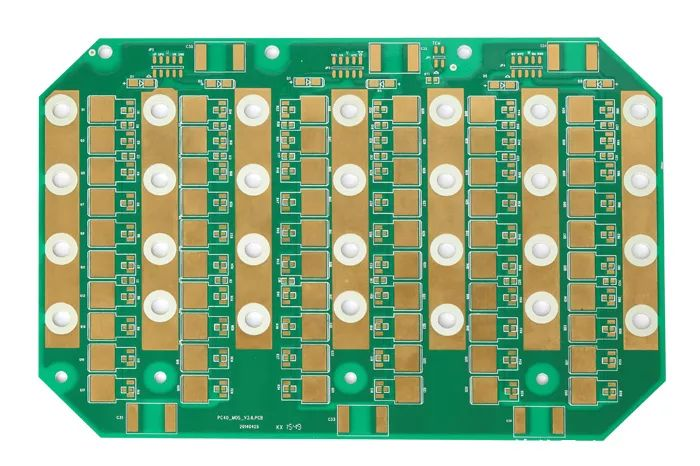

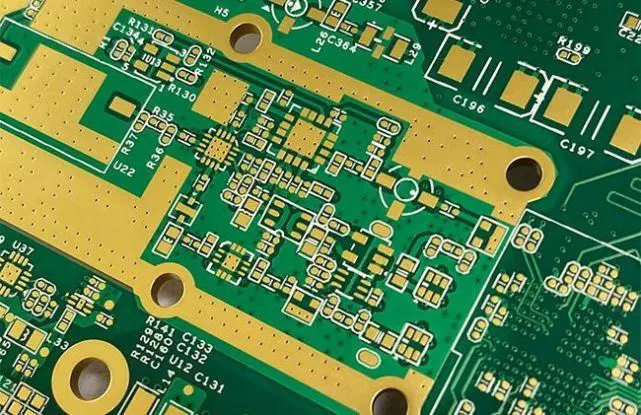

High-frequency PCB boards

High-frequency boards specifically refer to boards used in high-frequency environments where the electromagnetic frequency exceeds 1 GHz, and the selection of board materials is highly specialized.

Common high-frequency and high-speed circuit board materials include carbon-hydrogen resin, polytetrafluoroethylene (PTFE), liquid crystal polymer (LCP), and PPE/PPO. Due to the technical challenges in designing and manufacturing high-frequency boards, their prices are relatively high. Despite this, they are not widely used in consumer electronics but are more commonly found in specific industries.

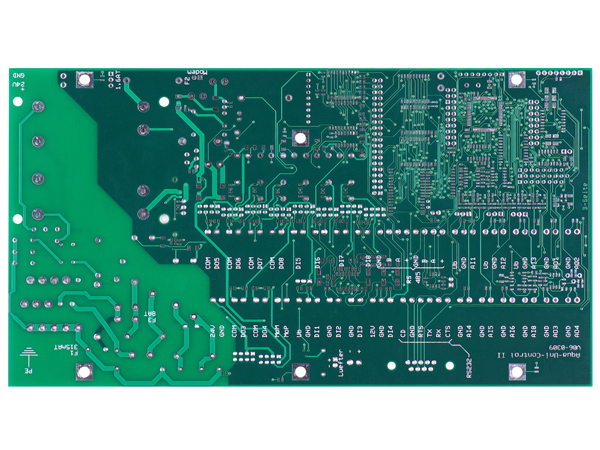

Paper-based PCB substrate

Phenolic PCB paper-based substrates are meticulously crafted from materials such as paper pulp and wood pulp, with wood pulp fiber paper being the primary component. This type of paper-based substrate is manufactured through a process of pressure-molding and synthesis using phenolic resin, thereby imparting unique circuit etching properties. However, most paper-based substrate materials lack fire-resistant properties; only those meeting the 94V0 standard possess flame-retardant characteristics.

Paper substrates are widely used in fields such as home appliances and switching power supplies due to their lightweight, environmentally friendly, and cost-effective characteristics. Common brands include Jiantou (KB character), Changchun (L character), Doosan (DS character), Changxing (EC character), and Hitachi (H character), among others. Additionally, paper-based substrates are highly favored for their low density and ability to be punched, with various material types available, such as XPC, FR-1, FR-2, FE-3, and 94V0.

Aluminum-based substrates

Aluminum-based substrates are single-sided boards composed of three layers: a circuit layer (copper foil), an insulating layer, and a metal base layer.

Their design is uniquely distinctive. Aluminum substrates have two sides: the white side is specifically designed for soldering LED leads, while the other side retains the natural color of aluminum. Since this side is entirely made of aluminum, it is limited to being used as a single-sided board. This type of aluminum substrate is widely used in LED lighting products, with its excellent heat dissipation performance being its greatest advantage. Additionally, FPC flexible boards are another important material in the electronics field and deserve attention.

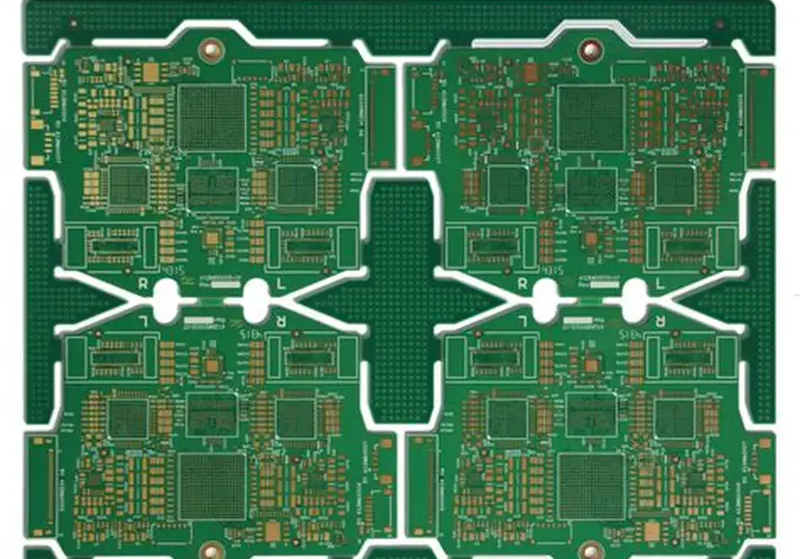

Composite Substrates

Composite substrates, also commonly referred to as powder boards, with CEM-1 boards being known as 22F in some regions.

They primarily refer to CEM-1 and CEM-3 composite copper-clad laminates. CEM-1 uses wood pulp fiber paper or cotton pulp fiber paper as the core reinforcement material, with glass fiber cloth as the surface reinforcement material. Both are impregnated with flame-retardant epoxy resin to form the copper-clad laminate. CEM-3, on the other hand, uses glass fiber paper as the core material, with glass fiber cloth as the surface reinforcement material, and is similarly treated with flame-retardant epoxy resin. These two types of copper-clad laminates are commonly available in the market and are more cost-effective compared to FR4-type laminates.

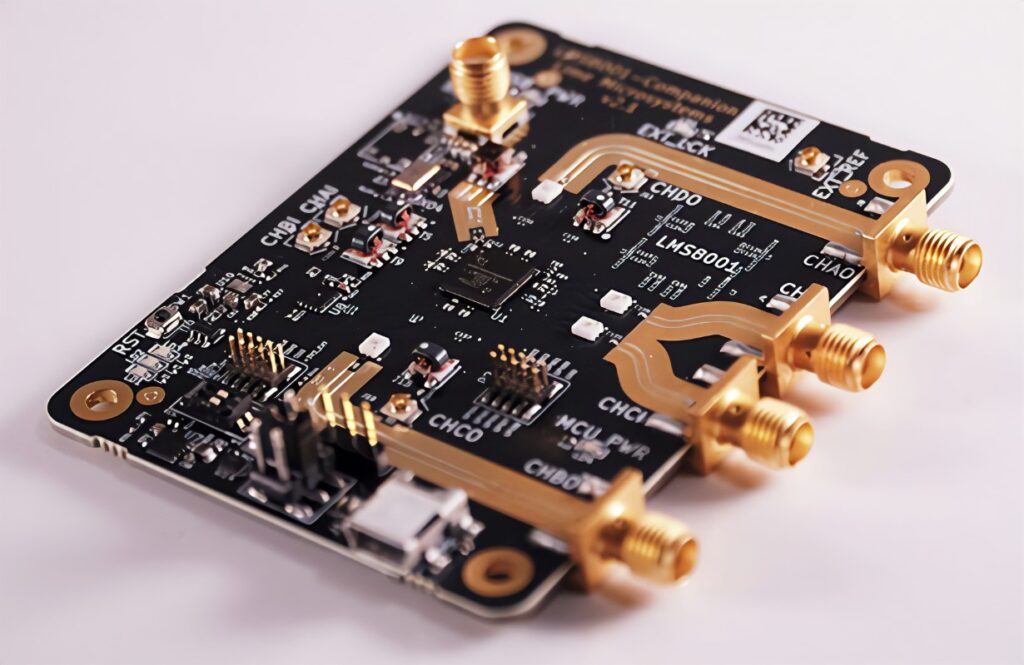

Carbon-hydrogen resin

Carbon-hydrogen resin is a widely used material that performs exceptionally well in high-frequency environments. Its unique physical and chemical properties make it one of the preferred materials for high-frequency PCB manufacturing.

In the market, carbon-hydrogen resin is highly regarded for its stability and high-temperature resistance, providing a solid foundation for high-frequency PCB applications.

BenChuang Electronics produces customized PCB boards. Contact us and send your specifications.