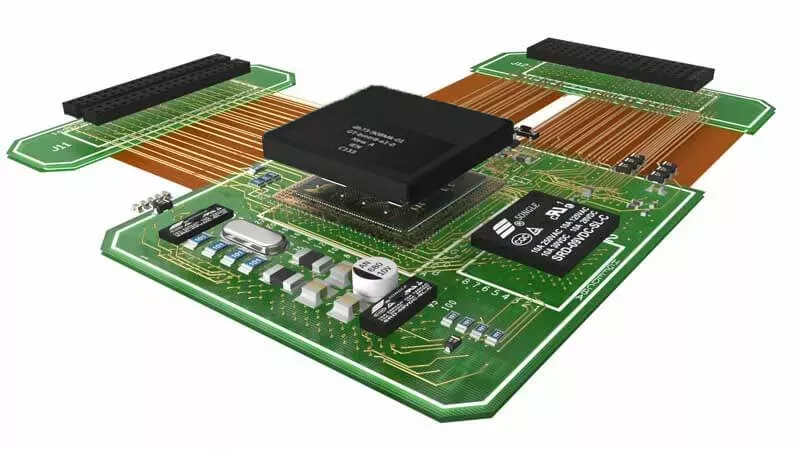

We manufacture PCBs and provide turnkey PCBA for projects that require stable quality and predictable delivery. Share your layer count, material, thickness, surface finish, and target quantity — we’ll review DFM points and quote quickly. Prototype builds and production runs are both supported.

View More-

Surface Mount Technology (SMT)

Fine-pitch placement for dense designs, with controlled reflow profiles to reduce defects and improve consistency.

-

Wave / Selective Soldering (THT)

Reliable soldering for through-hole parts such as connectors and power components.

-

Hand Soldering & Rework

Skilled hand soldering and rework for prototypes, special parts, and engineering changes.

-

Inspection & Functional Testing

AOI, ICT and functional testing options to verify assembly quality and basic performance.

-

BGA / QFN Soldering

Process control for complex packages, with inspection options to confirm solder joint reliability.

-

Final Assembly & Programming

Final assembly, basic programming support, and verification before shipment when required.

PCB & PCBA for Key Industries

View MoreTalk to an Engineer & Get a Quote

-

Engineering

Our highly experienced engineering team is at your service – from design to fabrication for an All-in-One solution

WhatsApp for Quote -

Manager

Our managerteam will be happy to provide you with a quote. Simply send us an email detailing your requirements and we’ll reply ASAP

WhatsApp for Quote

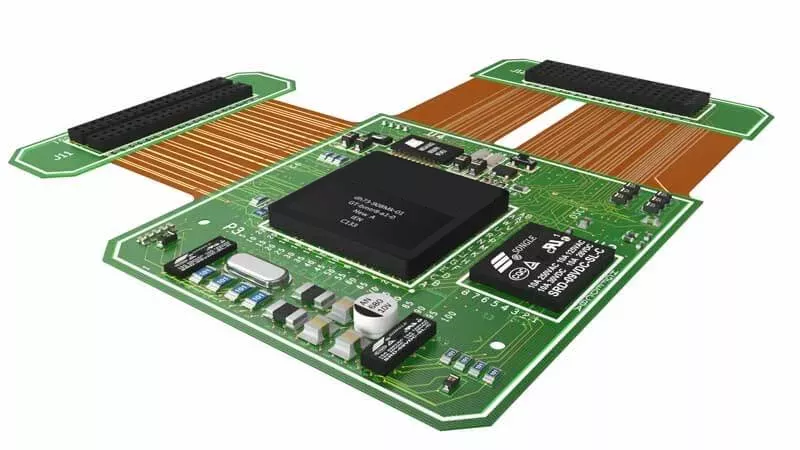

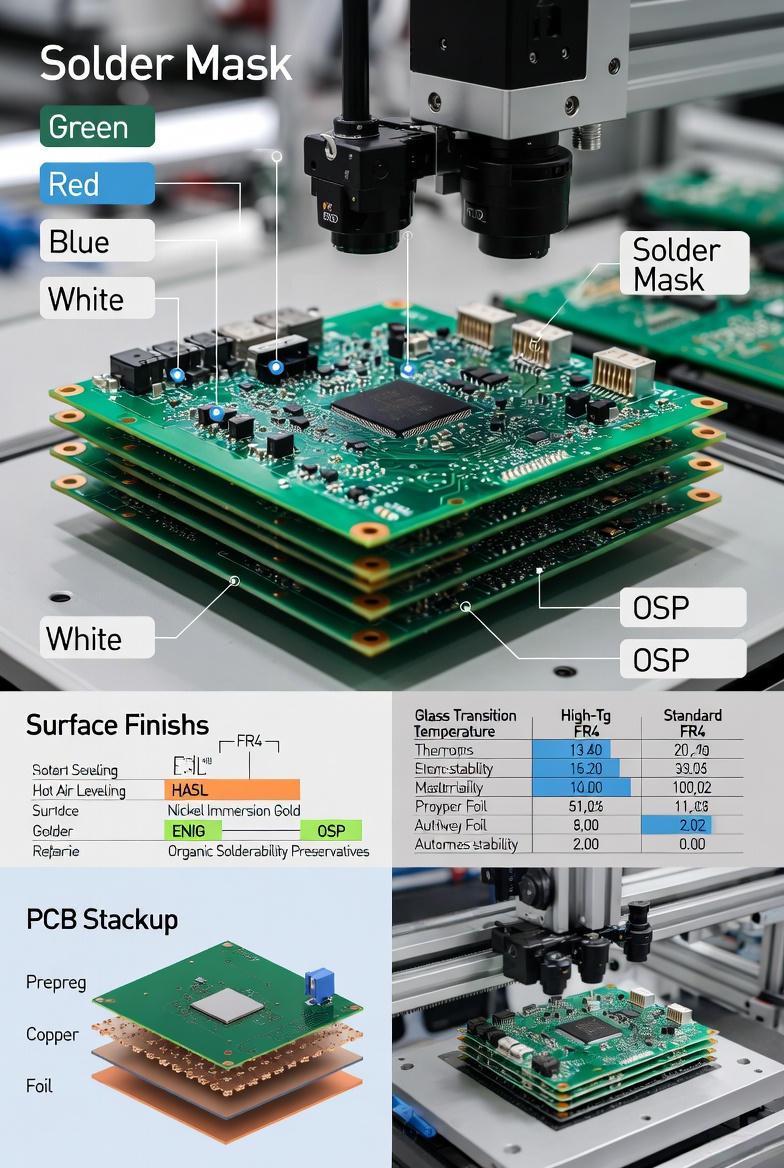

PCBA Capability

SMT + THT assembly with BGA/QFN support, inspection and testing options based on your requirements. Send your Gerber, BOM and assembly notes — we’ll confirm build feasibility, lead time and pricing.

View MorePCB Services

-

PCB Layout

Layout support with DFM considerations, stackup planning, and production-ready outputs.

-

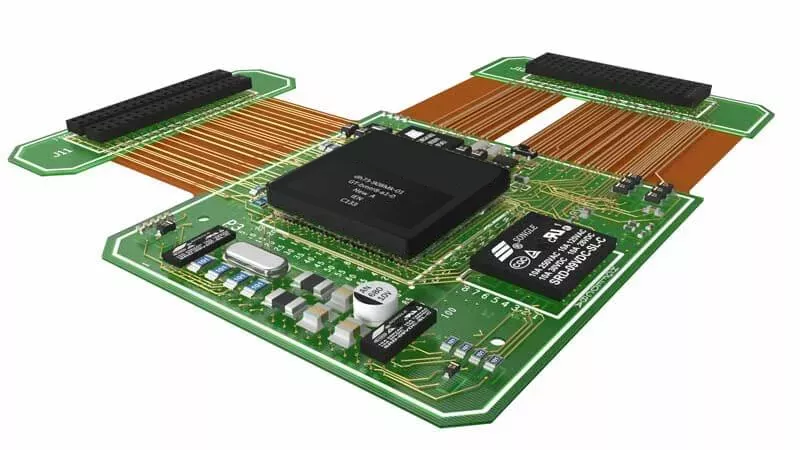

PCB Assembly

Prototype and production assembly with process control, clear build feedback, and consistent workmanship.

-

Full Turnkey

Turnkey sourcing + manufacturing coordination to keep BOM, schedule and quality under control.

Latest Updates in PCB & PCBA

-

Benchuang Electronics: China Multilayer PCBs Manufacturer

As a premier China Multilayer PCB Manufacturer established in 2007, Meizhou Benchuang Electronics Co., Ltd. (Benchuang) has earned a reputation for delivering high-reliability PCB fabrication services to the global market. Based in Guan...

2026-01-27 -

FR4 vs. Aluminum PCB: What is the Best Choice for High-Power LED Lighting?

Heat is the silent killer of LED performance. As an LED product designer, you know that managing junction temperature is the key to longevity and brightness. When designing the printed circuit board (PCB) for a new lighting product, the...

2026-01-05 -

10 Key Questions to Ask When Choosing a China FR4 PCB Manufacturer in 2026 (Green Solder Mask Tips Included)

In the competitive world of electronics manufacturing, selecting the right FR4 PCB manufacturer in China can make or break your project's success. FR4 remains the go-to material for most applications due to its excellent balance of cost...

2025-12-29