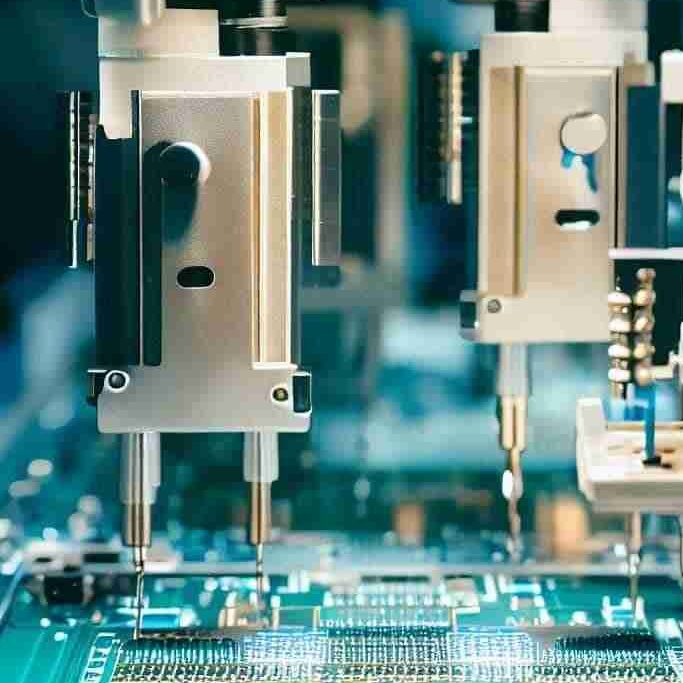

This article introduces the N types of fastening processes commonly used in PCBs across various industries. We hope that in the future, when designing PCBs, you will fully consider the advantages, disadvantages, and applicability of various fastening processes to select a design that not only meets reliability requirements but also offers the most cost-effective solution.

1. Screw Fastening

Screw fastening is one of the most commonly used and oldest fastening methods in PCBA. When you open a desktop computer or laptop, you will find that the motherboard is secured to the chassis using screws.

Screw fastening offers high reliability and is suitable for larger PCBs; however, the process of tightening screws takes a long time, resulting in high assembly costs. If users need to frequently disassemble and reassemble the PCB, this can lead to a poor user experience.

Even if screws must be used for reliability reasons, it is still important to minimize the number of screws. For more details, refer to this article:

Essentials | Cost-saving design: The evolution of server backplane fastening processes

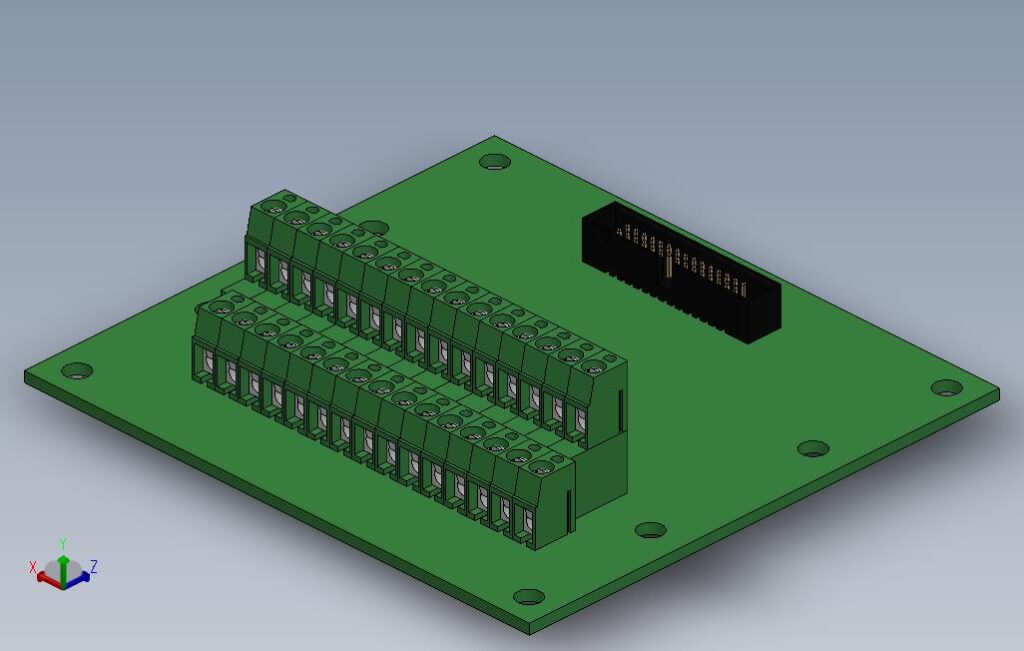

2. PCB spacers

PCB spacers enable quick installation and disassembly, avoiding the significant time wasted during screw tightening and removal processes.

Essentials | The N Methods of PCB Fastening: Don't Just Consider Screws—There Are Other Optimal Choices - Figure 11

3. Snap-in Fastening

When assembling PCBs onto plastic enclosures, snap-in fasteners can be used instead of screws for quick assembly and disassembly, provided there is sufficient space (the snap-in fasteners must have adequate length to ensure elasticity). This reduces assembly costs while enhancing user experience.

4. Upper and Lower Shell Fastening

When the PCB is small in size, direct clamping between the upper and lower shells can be considered to eliminate the need for additional fastening methods.

5. Hot Melt Fastening

When fixing the PCB to a plastic housing, hot-melt fastening can be used. Hot melt fastening is efficient and requires low equipment investment.

6. In-mold injection molding

For PCBs with cables, in-mold injection molding is often used to secure the PCB within the housing to achieve waterproofing, dustproofing, and dust resistance. One drawback of in-mold injection molding is the high injection temperature, which may damage components on the PCB; another drawback is the need to place the PCB into the mold first, which increases the injection molding cycle time.

7. Low-Pressure Injection Molding

Low-pressure injection molding (Low-pressure overmolding) appears similar to insert molding at first glance, but the two are fundamentally different processes. Low-pressure injection molding can be viewed as a simplified, low-pressure version of injection molding or as a process where adhesive is injected through the mold.

The surface of low-pressure injection molding is generally not scratch-resistant and prone to dirt, so additional enclosures may be required for applications with higher performance demands.

8. Encapsulation

PCBs are placed in plastic or metal enclosures and encapsulated, achieving waterproofing, dustproofing, and even heat dissipation while securing the components. The main drawback of encapsulation is the lengthy curing time.

Conclusion

Each of the above securing processes is only briefly introduced in this article. When actually applying these processes, readers are encouraged to use the search methods and techniques outlined in previous articles on this public account to conduct further research and learning.

The assembly cost for each fastening process must be accurately assessed based on factors such as required labor hours, number of workers, and labor rates, using the methods outlined in “Cost-Effective Product Design: The Path to Cost Reduction.”

Different products have different assembly costs for each fastening process, so it is difficult to simply state which fastening process has higher or lower assembly costs.

Additionally, PCB fastening processes include many other methods, such as adhesive-backed fastening and adhesive fastening. The above examples are merely intended to spark discussion, reminding engineers not to fixate on screws when selecting PCB fastening processes. Instead, they should explore mature solutions from other industries to broaden their horizons and design the best possible products.

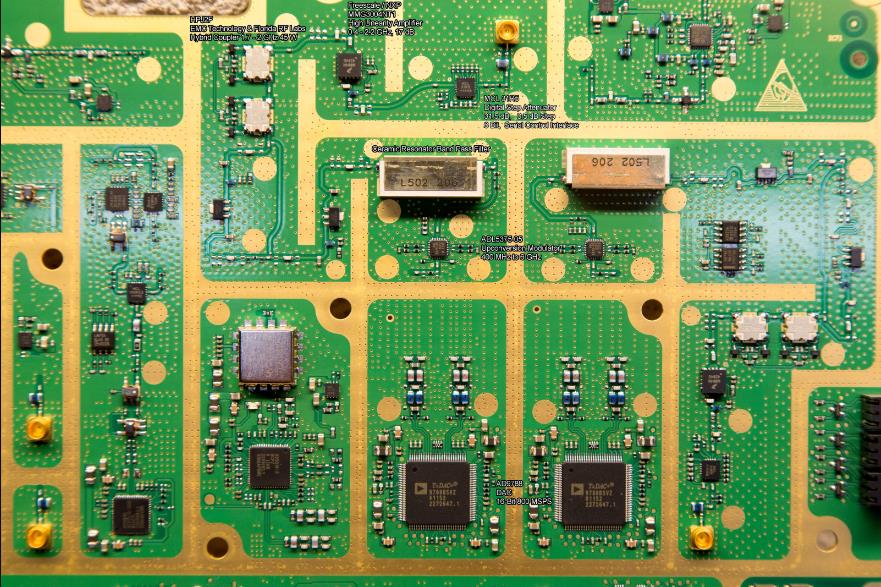

BenChuang Electronics produces customized PCB boards. Contact us and send your specifications.