Single-sided PCB

A single-sided PCB is the most basic type of printed circuit board, with components concentrated on one side and conductive traces on the other. Since conductive traces are only present on one side, it is called a single-sided PCB. It is primarily used in older circuits and simple electronic products.

Double-sided PCB

A double-sided PCB is a printed circuit board where conductive patterns are printed on both sides of a double-sided copper-clad board. Since conductive patterns are present on both sides, metalized holes are typically used to connect the conductive patterns on both sides. Such PCBs can route traces around to the other side through metal holes, allowing for interconnection, and are therefore suitable for more complex circuits.

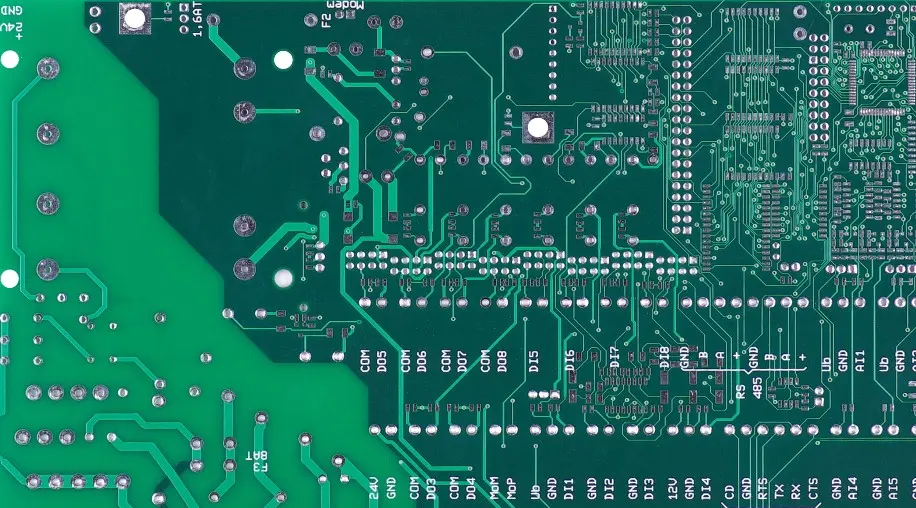

Multilayer PCB

Multilayer boards are printed circuit boards with three or more layers of conductive patterns. The inner layers are formed by laminating conductive patterns with insulating prepreg sheets, while the outer layers are made of copper foil, which is then pressed into a single unit.

To bring out the printed conductive lines sandwiched between the insulating substrates, the vias on multilayer boards must undergo metallization to connect them with the printed conductive lines within the insulating substrates. The production of conductive patterns on multilayer boards primarily uses photolithography, with the number of layers typically being even and including the two outer layers.

Rigid-flex PCB

Rigid-flex boards refer to printed circuit boards that incorporate one or more rigid zones and flexible zones, formed by laminating thin-layered flexible printed circuit board substrates and rigid printed circuit board substrates.

The advantage of rigid-flex boards is that they provide the structural support of rigid boards while retaining the bending characteristics of flexible boards, enabling them to meet three-dimensional assembly requirements. Rigid-flex boards are widely used in advanced medical electronic devices, portable cameras, and foldable computer devices, among other fields.

High-frequency PCB

High-frequency boards (High-frequency PCB) are also known as high-frequency communication circuit boards or radio frequency circuit boards. They are printed circuit boards manufactured using special low-dielectric constant and low-dielectric loss materials, featuring high electromagnetic frequencies.

High-frequency PCBs have stringent requirements for signal integrity and material processing, particularly in terms of graphic precision, layer alignment accuracy, and impedance control, resulting in higher costs. High-frequency PCBs are primarily used in communication base stations, microwave communication, satellite communication, and radar applications.

Other Product Structures

In addition to thick copper boards, high-frequency boards, high-speed boards, and metal substrates, there are other product structures of printed circuit boards, such as carbon film printed boards and surface-mount printed boards.

BenChuang Electronics produces customized PCB boards. Contact us and send your specifications.