Analysis of PCB Substrate Structure

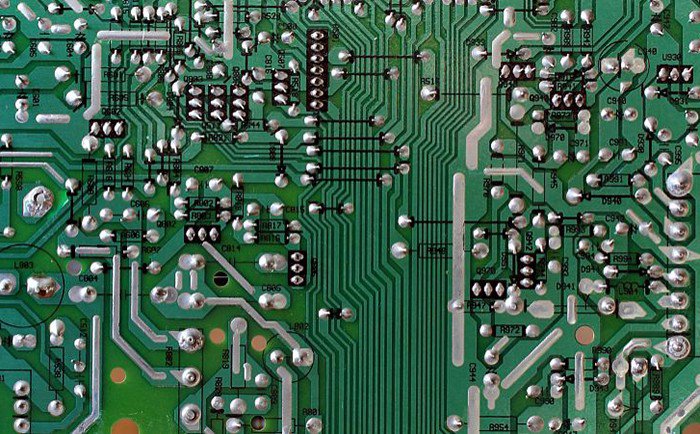

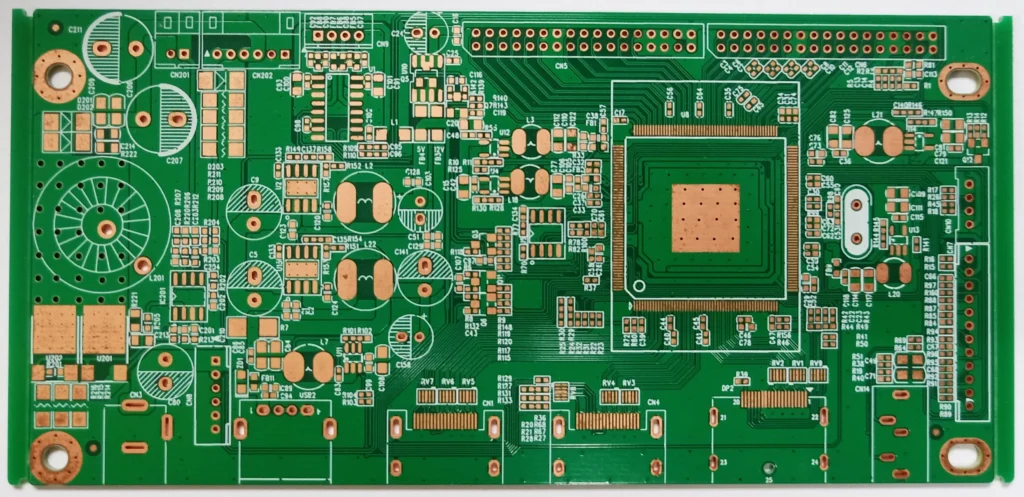

The core material of a PCB is copper-clad laminate (CCL), also known as copper-clad board or copper-clad sheet. This substrate forms the basic framework of the PCB.

The core components of a PCB include the substrate, copper foil, and adhesive. The substrate itself is formed by combining high-molecular synthetic resin with reinforcing materials to create an insulating layer. Its surface is covered with a layer of copper foil that exhibits excellent conductivity and solderability. The adhesive plays a crucial role in ensuring that the copper foil is securely bonded to the substrate.

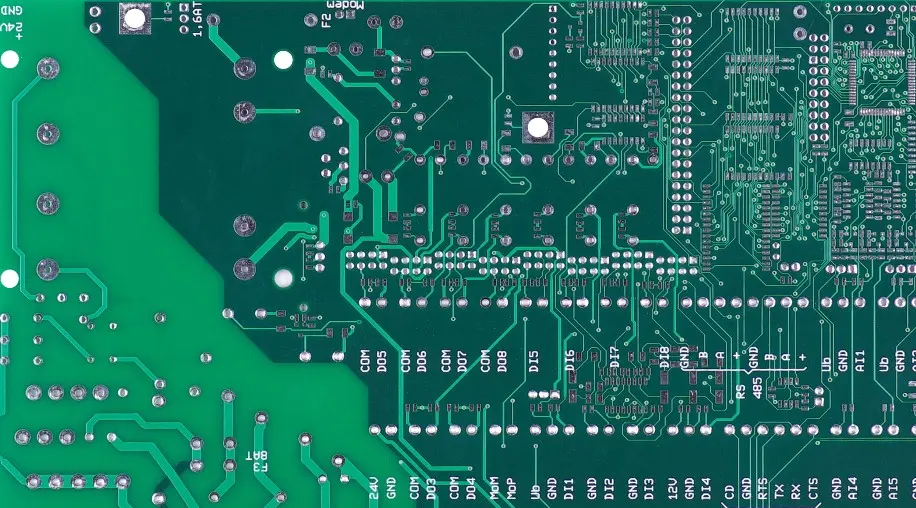

A basic four-layer board structure primarily consists of copper foil, prepreg, core board (here, the core board is a semi-finished product composed of prepreg and two layers of copper foil), and solder mask, among other elements. Through a series of precise manufacturing processes, these components are ultimately integrated into the printed circuit board we are familiar with.

PCB Material Classification

▲ Multi-dimensional Classification

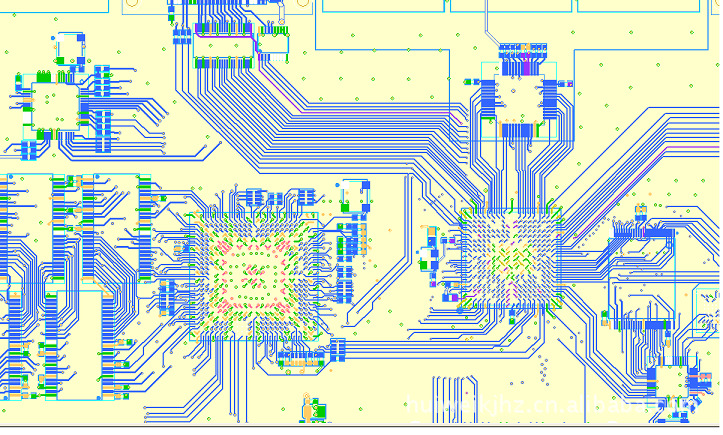

PCB materials can be classified from multiple dimensions, including mechanical rigidity, flame retardant rating, halogen presence, glass fiber cloth type, copper foil type, and Tg value. Specifically, based on mechanical rigidity, there are rigid boards and flexible boards; in terms of flame-retardant ratings, they are divided into flame-retardant and non-flame-retardant types, such as FR1, FR2, FR3, FR4, and FR5.

Regarding halogen content, substrate materials can be classified into halogen-containing and halogen-free types. Additionally, based on the type of glass fiber cloth, boards can be classified into types such as 106, 1067, and 1080. Copper foil type is also an important factor influencing board classification, including STD, RTF, and VLP. Furthermore, the Tg value of the board is an important classification criterion, with boards categorized into low-Tg, medium-Tg, and high-Tg boards.

▲ Performance and Applications

Loss level is another dimension for board classification, including standard loss boards, medium loss boards, low loss boards, and ultra-low loss boards. It is important to note that high-Tg, low-loss boards are often suitable for high-speed signal transmission but come at a relatively higher cost. When selecting boards, it is essential to choose cost-effective options based on actual requirements and performance specifications.

BenChuang Electronics produces customized PCB boards. Contact us and send your specifications.