Green Solder Mask vs Other Colors: 2025 Impact on PCB Costs, Lead Times & Yields Comparison

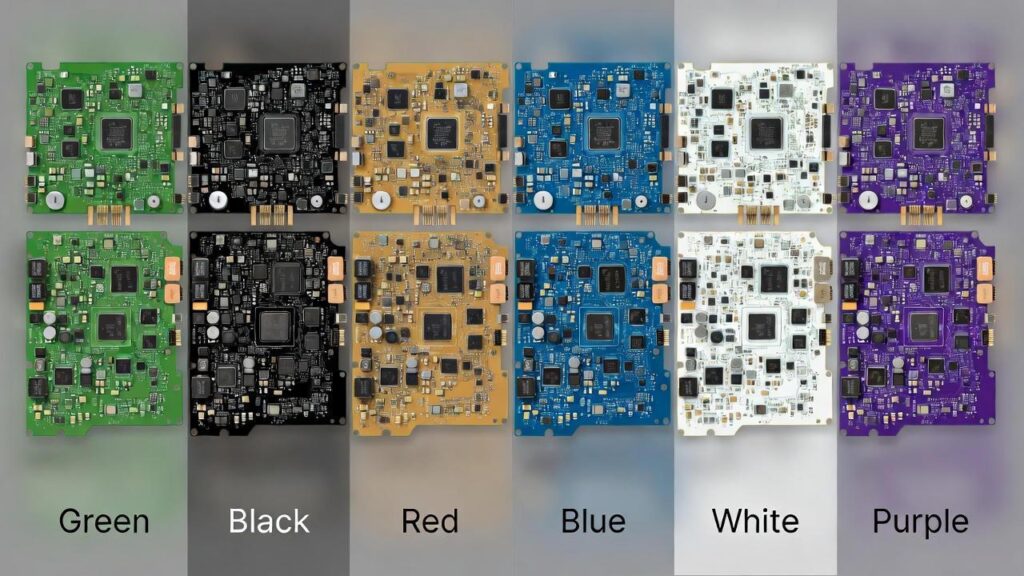

In 2025, while PCB designers have more solder mask color options than ever—from matte black for aesthetics to vibrant red or blue for branding—green remains the overwhelming industry standard. Why? It's not just tradition. Green solder mask delivers tangible advantages in manufacturing costs, lead times, and assembly yields, especially for FR4-based boards.

This article breaks down the real-world differences based on current industry data, supplier insights, and production trends. Whether you're prototyping a consumer gadget or scaling an industrial control board, understanding these impacts can save you significant time and money.

Key Factors Driving Solder Mask Choice in 2025

Solder mask (also called solder resist) protects copper traces and prevents bridging during assembly. Color choice affects more than looks—it influences:

- Visual Contrast for Inspection: Critical for Automated Optical Inspection (AOI) and manual checks.

- Supply Chain Availability: Standard colors are stockpiled; custom ones require special orders.

- Process Compatibility: Curing, adhesion, and thickness uniformity vary by pigment.

- Cost Structure: Material volume and setup fees.

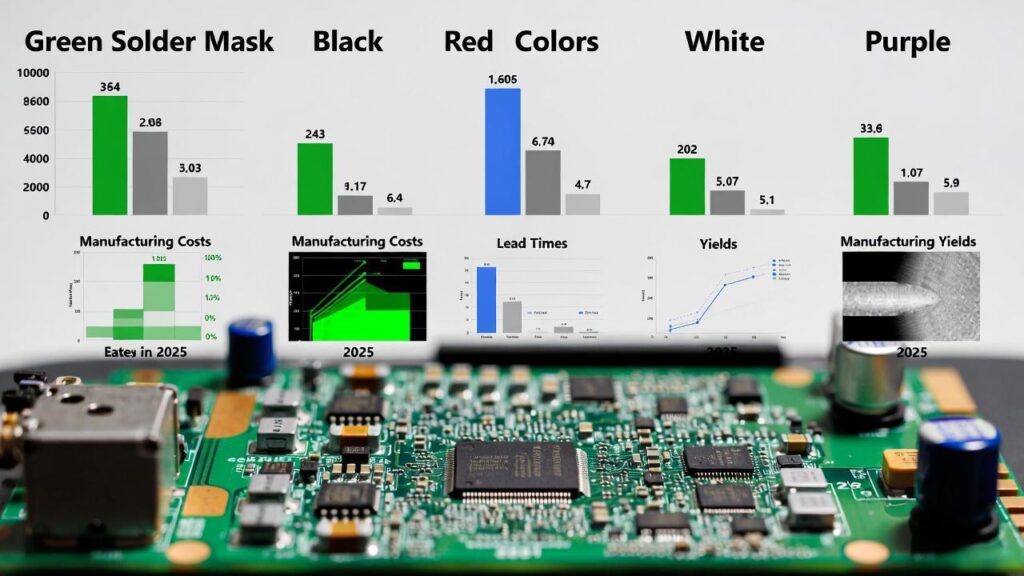

2025 Comparison: Green vs Other Popular Colors

Here's a data-driven breakdown using averages from leading Chinese manufacturers and industry reports (e.g., IPC surveys and supplier benchmarks in 2025):

| Aspect | Green (Standard) | Black/Matte Black | Red/Blue/Yellow | White/Purple |

|---|---|---|---|---|

| Material Cost Premium | Baseline (0%) | +10-25% | +15-40% | +30-60% |

| Lead Time Impact | Standard (no delay) | +1-3 days | +2-5 days | +3-7 days |

| AOI/Manual Inspection Contrast | Excellent (high contrast) | Poor (low contrast, higher false rejects) | Good (but less than green) | Very Poor (glare/reflection issues) |

| Typical Yield Improvement | Baseline (+0%) | -5-15% (more defects detected/rework) | -3-10% | -10-20% |

| Common Applications | Consumer, industrial, power | Aesthetics (LED/enclosures) | Branding (automotive, IoT) | High-visibility (displays) |

Sources: Aggregated from 2025 manufacturer data; green typically reduces overall project costs by 5-15% due to fewer reworks and faster cycles.

Why Green Excels in Inspection and Yields

The biggest advantage of green solder mask is superior contrast against copper traces, silkscreen, and solder joints. This makes defects like shorts, opens, or insufficient solder far easier to spot during AOI—now standard in high-volume production.

In 2025, with finer pitches (0.4mm BGA common) and denser designs, darker colors like black often increase false rejects or missed defects, leading to higher rework rates. White masks reflect light, causing glare in AOI cameras. Green strikes the perfect balance, boosting first-pass yields by 10-30% in many cases.

Cost and Lead Time Realities

Green is the most produced color globally, meaning:

- Bulk material availability: No waiting for pigment mixing.

- No extra setup fees: Unlike custom colors requiring dedicated runs.

- Faster turnaround: Prototypes in 5-7 days vs 10+ for exotic colors.

Non-green options add premiums because pigments are less common and require longer curing validation. For low-to-medium volumes (<5,000 pcs), the difference can add hundreds to thousands of dollars.

When to Choose Non-Green (And When Not To)

- Choose non-green if: Branding demands it (e.g., visible PCBs in clear enclosures), or specific functional needs (e.g., matte black for heat dissipation in LEDs).

- Stick with green if: Cost, speed, and reliability are priorities—especially for prototypes transitioning to production.

Conclusion: Green Remains King in 2025—for Good Reason

Despite trendy alternatives, green solder mask continues to dominate because it directly improves manufacturing efficiency, reduces costs, shortens lead times, and maximizes yields. For most FR4 PCB projects, it's the smartest default choice.

At Benchuang Precision Electronics, we specialize in high-quality green FR4 PCBs optimized for fast prototyping and seamless scaling. Our team provides free DFM reviews to ensure your design leverages green mask advantages fully—whether standard or high-Tg FR4.

Ready to optimize your next build? Send your Gerber files to William@bcpcbsz.com or WhatsApp +86 17724684094 for a quick quote, expert recommendations, and no-obligation engineering feedback. Let's make your project more reliable and cost-effective.