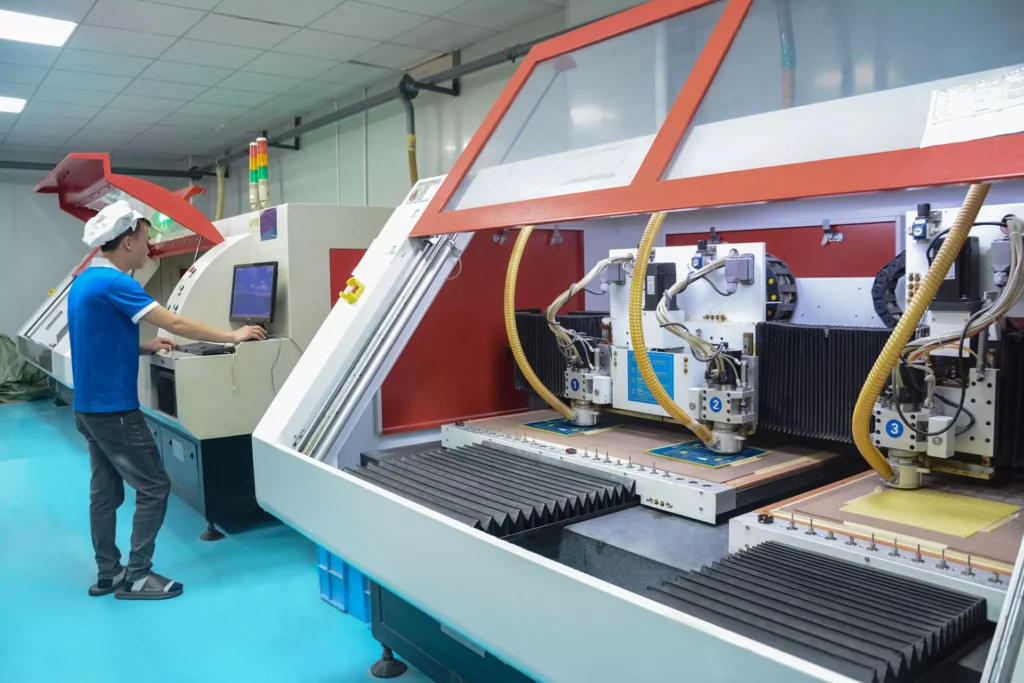

The DES (Direct Etching System) line etching machine is a vital tool in the production of printed circuit boards (PCBs), designed to remove unwanted copper layers from the PCB surface, thereby creating the precise circuit patterns required for functional connections. This machine uses either acidic or alkaline solutions to etch away copper under controlled temperature and pressure conditions, allowing for the formation of intricate copper traces and gaps on the PCB.

Key benefits of the DES line etching machine include:

- Precise Circuit Formation: By efficiently removing unwanted copper, the DES line etching machine helps create accurate and high-quality circuit patterns on PCBs.

- Efficient Large-Scale Production: It is highly suitable for large-scale PCB manufacturing, enabling quick and consistent etching of multiple boards.

- Customization and Flexibility: The etching process can be tailored to create various circuit designs, making the machine adaptable for different PCB applications.

- Enhanced Production Speed: With the ability to complete the etching process rapidly, the DES line etching machine increases overall manufacturing efficiency.

- Cost-Effective: By automating the etching process, manufacturers can reduce labor costs while maintaining consistent quality across large batches of PCBs.

In large-scale PCB production, the DES line etching machine plays a crucial role in ensuring the accuracy, quality, and efficiency of the etching process, contributing to the overall success of PCB manufacturing.