BenChuang Electronics in Medical Electronics: PCB Design & Manufacturing Challenges and Solutions

1. Special PCB Requirements for Medical Electronics

1.1 Durability and Reliability

Medical devices are often exposed to extreme environmental conditions, including temperature fluctuations, high humidity, and physical vibrations. These harsh conditions demand PCBs for medical electronics that can withstand long-term usage without compromising performance.

- BenChuang Electronics addresses these challenges by selecting high-temperature substrates and employing specialized manufacturing processes to enhance the durability of the PCBs used in medical applications. Our multilayer PCBs ensure superior reliability, even in the most demanding environments, such as operating rooms and emergency rooms.

- Additionally, we integrate shock-resistant and vibration-dampening technologies into our custom PCB designs for medical devices, ensuring that devices such as portable heart monitors or surgical tools can withstand physical impacts while maintaining their operational integrity.

1.2 Precision and High-Density Design

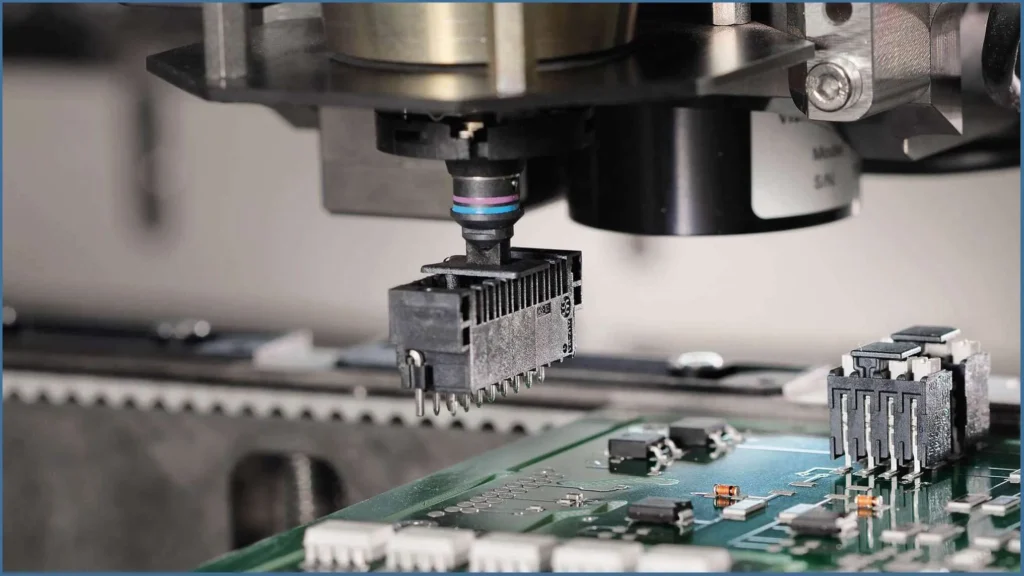

Medical devices require PCBs that are not only accurate but also compact. Whether it's a diagnostic tool or an implantable device, the PCB design must be optimized for small spaces without compromising functionality. Medical devices often require high-density interconnect (HDI) PCBs to maximize performance while minimizing size.

- At BenChuang Electronics, we excel in creating high-precision PCBs for medical devices using HDI technology. This allows us to offer micro-sized PCBs with tight tolerances, ensuring medical devices deliver accurate readings and consistent performance.

1.3 Electromagnetic Interference (EMI) Management

Electromagnetic interference (EMI) is a significant concern in medical electronics. The complex environments of hospitals, where multiple electronic devices operate simultaneously, can result in signal interference that affects the reliability and accuracy of medical devices.

- BenChuang Electronics employs advanced EMI management techniques to mitigate these issues. From optimizing PCB layout to incorporating electromagnetic shielding and differential signal routing, we ensure that medical devices can operate without disruption. Our PCBs for medical applications are designed to meet strict EMC (Electromagnetic Compatibility) standards, making them suitable for use in sensitive medical environments.

2. Solutions: BenChuang Electronics’ Technological Edge

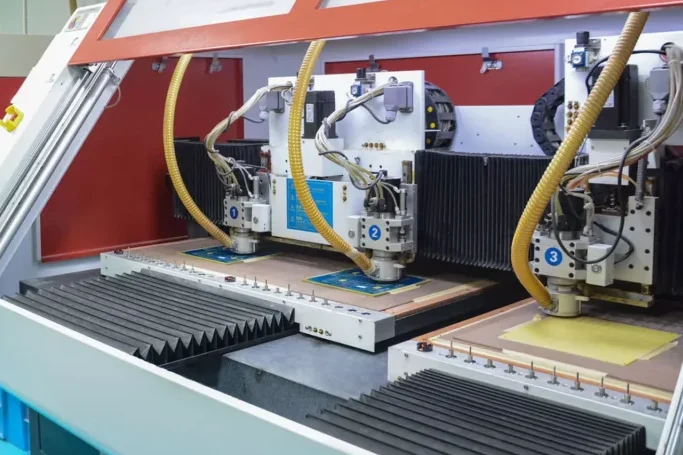

2.1 High-Precision Design and Manufacturing

At BenChuang Electronics, we prioritize precision in every step of the PCB design and manufacturing process. Our turnkey PCB solutions for medical devices allow us to oversee the entire lifecycle of the product—from concept to mass production—ensuring that every aspect meets our high standards.

- With our ability to produce fine-pitch components, we provide PCB solutions for medical electronics that support the most sophisticated medical applications. We guarantee that all our PCB assemblies are meticulously tested for accuracy, durability, and functionality, ensuring the final product exceeds industry standards.

2.2 EMI Management and Power Optimization

Electromagnetic interference (EMI) can severely impact the performance of medical devices. BenChuang Electronics integrates EMI shielding and advanced signal filtering into our designs to ensure stable and interference-free operation. Additionally, we utilize power decoupling capacitors to minimize noise and ensure a clean, stable power supply for sensitive medical equipment.

- By employing these advanced techniques, we ensure that BenChuang’s PCBs maintain the highest levels of EMC compliance, meeting the rigorous standards set for medical applications.

2.3 Innovative Materials and Processes

We continuously innovate in terms of PCB materials and processes to stay ahead of industry demands. At BenChuang Electronics, we use environmentally friendly materials, such as RoHS-compliant substrates, to meet sustainability requirements without sacrificing performance.

- We also offer specialized flexible PCBs for medical devices that require bending or compact form factors. This ensures that BenChuang Electronics can provide tailored solutions for the most complex and space-constrained medical devices.

3. Case Studies: Successful Applications

3.1 Patient Monitoring System PCBs

One of our major achievements has been providing PCB manufacturing services for patient monitoring systems used in hospitals worldwide. These devices require continuous, real-time data collection, and the PCBs must be designed to maintain accuracy even in high-vibration environments.

- BenChuang Electronics utilized multilayer PCBs and EMI shielding to ensure stable and reliable performance, even in noisy hospital environments. The result was a more efficient and durable monitoring system, improving patient care while ensuring compliance with medical standards.

3.2 Implantable Device PCBs

We also specialize in providing PCB solutions for implantable devices such as pacemakers and neurostimulators. These devices must meet the highest standards of reliability and biocompatibility due to their direct interaction with the human body.

- For these projects, BenChuang Electronics utilized biocompatible materials and advanced HDI techniques to create compact, durable, and highly accurate PCBs for medical devices. These devices are now used in hospitals around the world, helping patients with critical conditions live healthier lives.

4. Conclusion and Future Outlook

As a leader in PCB manufacturing for the medical electronics industry, BenChuang Electronics is committed to continuously innovating to meet the evolving needs of this dynamic sector. Our expertise in precision PCB design, EMI management, and material selection allows us to deliver turnkey solutions that not only meet but exceed industry standards.

We are dedicated to providing B2B customers with reliable, high-performance PCB solutions for medical electronics that improve the lives of patients while ensuring the utmost safety and reliability.