Heat is the silent killer of LED performance. As an LED product designer, you know that managing junction temperature is the key to longevity and brightness. When designing the printed circuit board (PCB) for a new lighting product, the most critical decision often happens before the first trace is routed: Choosing the substrate material.

Should you stick with the cost-effective industry standard (FR4), or is it time to upgrade to a thermal management powerhouse like Aluminum (Metal Core)?

In this guide, we break down the differences to help you manufacture the most reliable product.

1. FR4 PCBs: The Cost-Effective "Insulator"

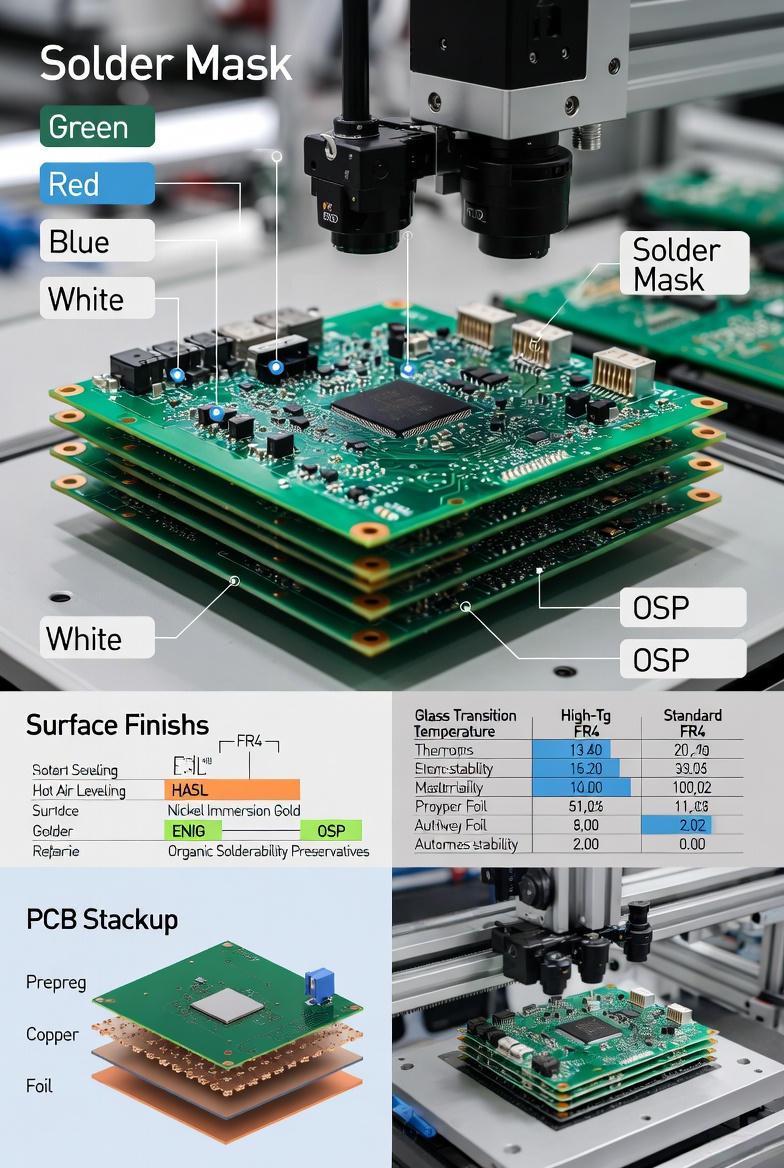

FR4 (Flame Retardant 4) is the backbone of the electronics industry. It is composed of woven fiberglass cloth with an epoxy resin binder.

When to use FR4: FR4 is an excellent electrical insulator, but it is also a thermal insulator. Its thermal conductivity is typically low (around 0.25 to 0.3 W/m·K). This means heat tends to stay trapped near the component.

However, FR4 is still a valid choice for:

- LED Drivers & Controllers: The control logic usually generates less heat than the LED chips themselves.

- Low-Power Indicator Lights: Simple status LEDs don't require aggressive cooling.

- Cost-Sensitive Projects: If the design allows for large copper pours and thermal vias, FR4 can sometimes suffice for mid-power applications.

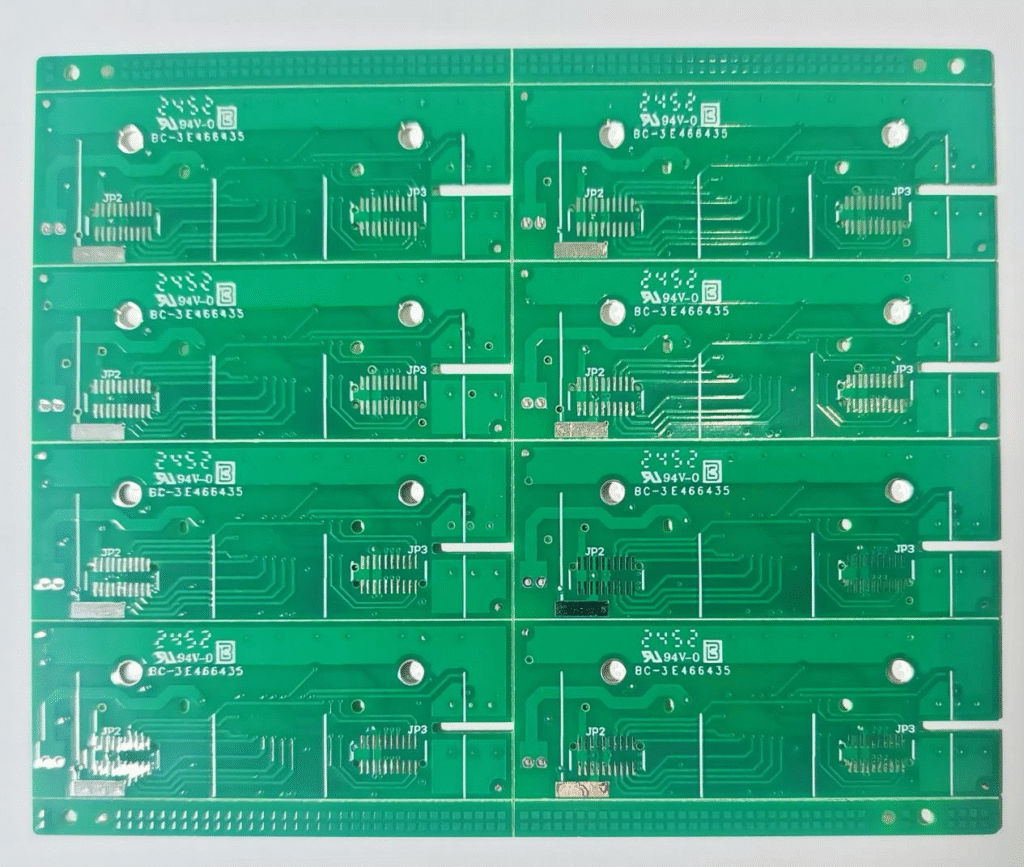

If your project involves general control circuits or low-heat applications, check out our FR4 Green PCB for Electronics. These boards offer versatility and complex multi-layer routing capabilities that metal boards often cannot match.

2. Aluminum (MCPCB): The High-Power Specialist

When we step into the territory of High-Power LED Lighting (such as street lights, automotive headlights, or grow lights), FR4 often fails. The heat simply cannot escape fast enough, leading to lumen depreciation (dimming) and chip failure.

This is where Metal Core PCBs (MCPCB) shine.

An Aluminum PCB features a thin layer of thermally conductive dielectric material sandwiched between the copper foil and a metal base. This structure acts as a heat sink, actively pulling heat away from the LED.

Why Aluminum is the Best Choice for Power LEDs:

- High Thermal Conductivity: Typically 1.0W/m·K to 3.0W/m·K (or higher), which is 5 to 10 times more efficient than FR4.

- Dimensional Stability: Aluminum is more rigid and durable, ideal for harsh environments.

- Space Saving: Because the PCB itself dissipates heat, you can often reduce the size of external heat sinks.

For designs utilizing high-wattage chips (like CREE, Osram, or Nichia), we strongly recommend using Aluminum PCB (MCPCB) for LED Lighting Modules. These boards are specifically engineered to keep your LED junction temperatures within safe limits.

Summary: The Decision Matrix

To make your decision easier, compare your project needs against this table:

| Feature | FR4 PCB | Aluminum PCB (MCPCB) |

|---|---|---|

| Primary Material | Fiberglass & Epoxy | Aluminum Alloy & Dielectric |

| Thermal Conductivity | Low (~0.3 W/m·K) | High (1.0 - 3.0+ W/m·K) |

| Best For | Logic, Drivers, Low-power strips | High-Power Downlights, Spotlights |

| Cost | Lower | Moderate |

| Our Solution | View FR4 PCB Products | View Aluminum PCB Products |

Conclusion

There is no "bad" material, only the wrong application.

If you are designing the driver circuitry, stick with FR4. It allows for complex routing and is cost-efficient. If you are designing the LED light engine itself—especially for 1W+ LEDs—Aluminum is not just an option; it is a necessity for reliability.

Still not sure about the thermal stack-up? At BCPCBSZ, we specialize in both technologies. Whether you need a complex multi-layer FR4 board or a high-thermal-conductivity aluminum board, our engineers can review your Gerber files to ensure manufacturability.

Contact us today or upload your files for a quick quote!