Flexible PCBs for Consumer Electronics: Turning Tight Spaces into Reliable Connections

Open up a modern smartphone or smartwatch and you’ll notice something important:

there’s almost no wasted space.

Batteries are larger, housings are slimmer, cameras are stacked, and boards are packed edge-to-edge. In this environment, traditional rigid PCBs and cable harnesses alone can’t solve every routing and packaging problem.

That’s where flexible PCBs (FPCs) become the quiet hero – enabling reliable, high-density connections inside extremely limited spaces.

This article takes the example of one of our typical FPC structures and explains how its design, materials and reliability directly support next-generation consumer electronics – and how you can work with us to turn your concept into a manufacturable flex solution.

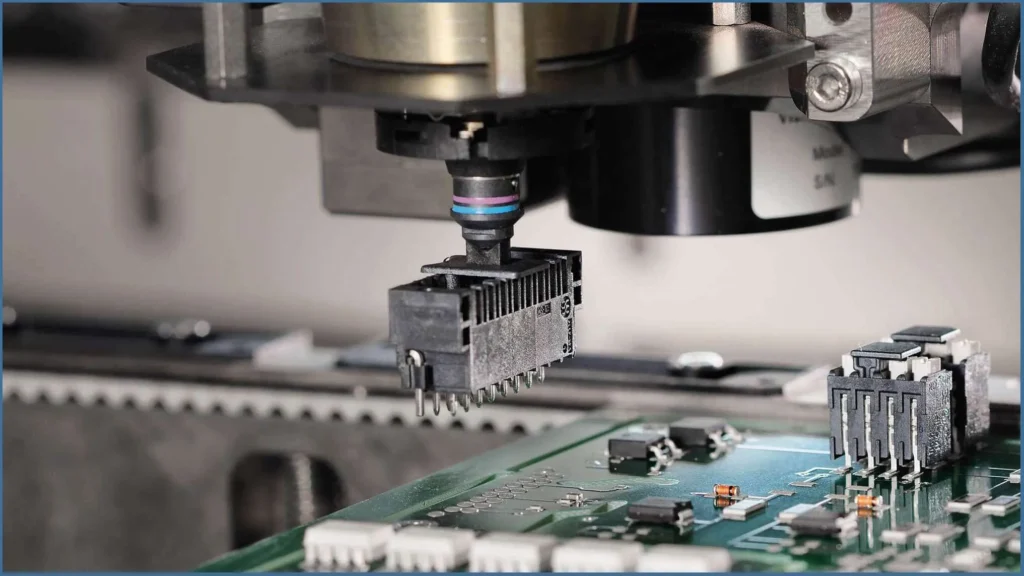

What This FPC Looks Like in a Real Device

The product featured on this page is a flexible printed circuit board used widely in consumer electronics such as smartphones and smartwatches.

Key characteristics:

- Green coverlay film as the main body

- Fine circuit line width/spacing: 0.1 mm / 0.1 mm

- Substrate thickness: only 0.05 mm

- Bending endurance: tested to exceed 100,000 cycles

- Matched with high-precision connectors for stable board-to-board connection

In real products, FPCs like this are typically used for:

- Signal transmission between smartphone screen and main board

- Interconnection between camera modules, sensors and core logic boards

- Internal links in smartwatches, fitness bands and other wearables

In other words, it’s the hidden “bridge” that keeps your slim, curved industrial design and your high-speed electronics working together reliably.

Why These Specs Matter for Consumer Electronics

For a casual user, “0.1 mm line width” and “100,000 bends” sound like engineer language. For you as a device designer or buyer, they translate into real competitive advantages.

1. 0.1 mm / 0.1 mm Line Width & Spacing: High Density in Tiny Footprints

With 0.1 mm / 0.1 mm (4/4 mil) line/space, you can:

- Route high I/O count connectors in a limited connector footprint

- Support high-pixel cameras, high-resolution displays, multi-sensor modules

- Keep your overall FPC size small while still carrying all necessary signals

This is particularly important around:

- Display FPCs connecting AMOLED screens to the driver board

- Camera FPCs with multiple signal pairs for image data, autofocus, OIS, etc.

- Wearables, where the board must wrap around tight radii without sacrificing routing capacity

High-density routing allows you to say “yes” to more features without saying “no” to compact design.

2. 0.05 mm Substrate: Ultra-Thin, Ultra-Flexible

A substrate thickness of only 0.05 mm makes the FPC:

- Extremely flexible – easy to fold, wrap, or snake through device cavities

- Space-saving – leaves room for thicker batteries, bigger speakers, or extra modules

- Lightweight – ideal for long-term wearable comfort

For smartphone and smartwatch engineers, this opens options such as:

- Adding side buttons, under-display sensors or antennas without increasing device thickness

- Designing complex hinge or sliding mechanisms where the FPC must pass through very narrow channels

- Reducing the mechanical stress on connectors by enabling smooth bending profiles

3. >100,000 Bending Cycles: Built for Real Users, Not Just Lab Prototypes

Consumer electronics see daily, uncontrolled use:

- Screens are opened and closed

- Watches are strapped on and off

- Devices are put in pockets, dropped, twisted, and carried everywhere

An FPC tested to more than 100,000 bending cycles means:

- It can survive long-term dynamic flexing in hinges and moving parts

- It helps reduce warranty claims and returns caused by internal connection failures

- Your brand reputation isn’t compromised by hidden internal weaknesses

This level of bend endurance is exactly what you need for foldable phones, flip cameras, TWS charging lids and watch-style wearables.

From Wire Harness to FPC: What You Gain

Many older or lower-cost designs still rely on wire harnesses and manual connectors inside the housing. Compared to that, a custom FPC like this brings multiple advantages:

Cleaner Internal Architecture

- One integrated FPC replaces a bundle of wires and multiple connectors

- Fewer manual assembly operations → more consistent quality

- Easier automated assembly (SMT + connector insertion)

Better Electrical Performance

- Controlled trace geometry and consistent impedance

- Reduced risk of loose wires, broken solder joints, or connector fatigue

- More stable high-speed signal transmission for display and camera interfaces

Lower Total Cost of Ownership

Even if the FPC itself is more sophisticated than a simple cable, you can save money through:

- Reduced assembly time and labor

- Lower rework and failure rate

- Better yield in mass production

For brands serious about scaling a consumer electronic product line, this often leads to a better long-term cost structure than “cheap-looking” harness-based solutions.

Typical Application Scenarios for This FPC Structure

Based on its specs, this type of FPC fits particularly well in the following scenarios:

1. Smartphone Display–Main Board Connection

- High-density interface between AMOLED/LCD display and motherboard

- Repeated, small deflections due to daily handling

- Demands for thin, foldable or curved display assemblies

2. Smartwatch / Fitness Band Core Board

- Compact main board connected to sensors, screen, and battery via flex

- Continuous micro-bending as the device follows wrist curvature

- Requirement for light weight and skin-contact comfort

3. TWS Earphones & Charging Cases

- Miniature FPCs inside earbuds for batteries, drivers and microphones

- Flex circuits in charging cases connecting indicator LEDs, ports and control boards

- Tight internal structure where every 0.1 mm of thickness counts

4. Foldable / Hinge-Based Devices

- Dynamic bending in fold hinges, sliders or rotating camera modules

- Need to withstand frequent opening and closing without fatigue failure

If your application sounds similar to any of these, this FPC specification is a strong starting point.

How Benchuang Supports Your Flexible PCB Project

We don’t just manufacture – we co-engineer with your team to make sure the flex works in real devices, not just in CAD.

Engineering & DFM Collaboration

You can send us:

- Gerber or ODB++ files

- Mechanical drawings and 3D models

- Key requirements (bending radius, dynamic/static areas, interface type, etc.)

Our engineers will provide:

- Recommendations on bend radius, layer stack-up, stiffener placement

- Suggestions to protect copper in dynamic flex zones

- Optimizations around connector footprint, pad shapes and panelization

Reliable Production for Consumer-Grade Volumes

Whether you are:

- Validating early prototypes (dozens to a few hundred pieces), or

- Scaling an existing design to mass production

…we can match process capability and capacity to your needs. Our goal is to help you move from sample to stable mass production smoothly, without surprises.

Turn Your Next Device Concept into a Reliable Flex Design

If you’re working on:

- A new smartphone, smartwatch, fitness tracker or TWS device

- A redesign to make an existing product thinner, lighter or more reliable

- Migrating from traditional wire harness to flexible PCB interconnects

then now is the time to talk to an FPC manufacturer who understands both consumer electronics constraints and mass-production reality.

You already know what you want the product to look like. We help ensure the internal flexible connections can support that vision for the entire product lifecycle.

Ready to Discuss Your Flexible PCB Design?

Share your concept or existing files and let our team review them for:

- Feasibility and risk points (bending, thickness, connector stress)

- Cost-effective material and stack-up options

- Lead time and sample plan for your project

You can reach us via:

- 📧 Email: William@bcpcbsz.com

- 📱 WhatsApp: +86 17724684094

Or simply submit the inquiry form on this page with your project details and we’ll get back to you with engineering feedback and a quotation.