Double-Sided PCBs Export: How BenChuang Electronics Helps EMS Procurement Teams Cut Board Cost

Double-sided boards (2L) account for 65% of the volume that ships from our Shenzhen factory each week. The reason is simple: a 2L FR-4 panel gives OEMs twice the routing space of a single-sided board without the lamination cost of a multilayer build. For overseas buyers managing BOM cost and looking for a reliable PCB factory partner in China, the double-sided PCB is the workhorse that hits most commercial and industrial specs at the lowest unit price.

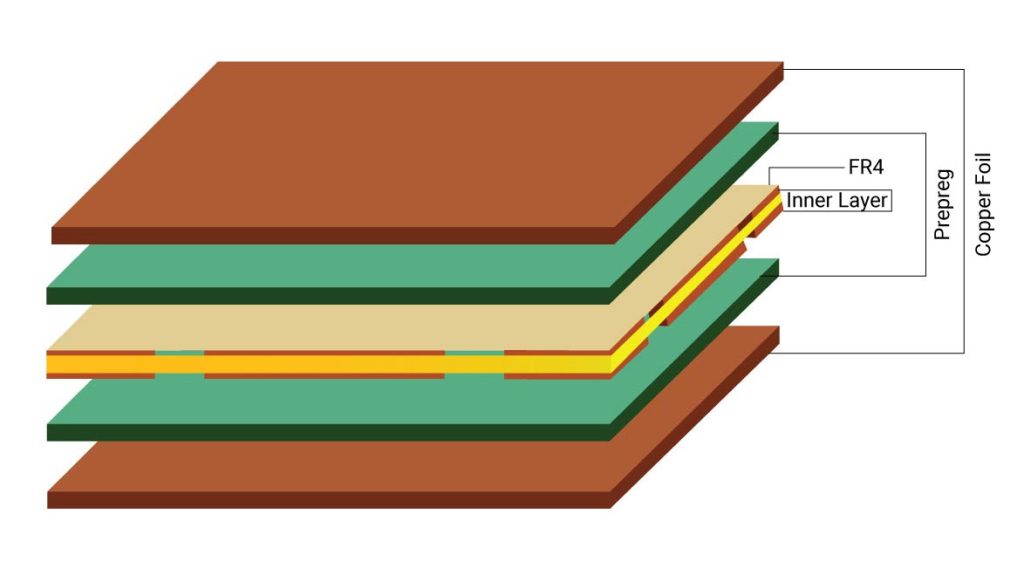

2L Materials & Stack-Up: What We Quote Every Day

Laminate

Shengyi S1170 (TG 135 °C) is our default FR-4. We stock 0.8 mm, 1.0 mm and 1.6 mm cores year-round. For lead-free assembly, we switch to S1170G (TG 150 °C) – same price, no tooling penalty. One U.S. EMS customer runs 1.0 mm for all IoT gateways; the thinner core cuts PCB weight by 18% and saves US$0.03 per sq. in. on freight.

Copper

1 oz (35 µm) each side is standard. 2 oz outer copper adds US$0.02 per sq. in. and one extra plating cycle (lead-time +24 h). We see 2 oz most often in LED driver designs where trace heating is a concern.

Drilling

Min. mechanical drill is 0.2 mm. We can achieve 0.15 mm, but tool wear increases the cost by +8%. In our free DFM review, we always ask: "Can you relax to 0.2 mm?" Nine times out of ten, the answer is yes, and the quote drops 5%.

Surface finish

HASL-LF is the daily bath; flatness ±25 µm, shelf life 12 months, no surcharge. ENIG adds US$0.08 per sq. in. (2–3 µm Ni, 0.05 µm Au); we run ENIG three shifts per week, so the lead time remains at 5 days. OSP is cost-neutral and fine for 0.5 mm-pitch SMT, but shelf life is only 6 months.

Quality Control for Export: What 100% AOI Actually Means

Every panel goes through AOI after etch. We scan for opens, shorts, and copper line width ±20%. Rejects route to a second etch cycle if repairable; scrap rate on 2L runs 0.8% in 2024. That figure came from the MES; we count every panel that hits the recycling bin.

Flying probe (Hitachi high-speed) tests all nets at 50 V isolation. The .odb++ test file ships with the boards; one German OEM customer uses it for incoming inspection and cuts their own test time by two hours per lot.

Two micro-section coupons per lot are read under 200× scope for copper thickness, hole-wall plating and dielectric. Photos are emailed with the C of C. If a batch fails on hole-wall copper <20 µm, we replate and ship a new section photo before the boards leave the building.

When to Upgrade: 2L vs. 4L Cost Impact

If your design needs controlled impedance or more than two power domains, 4L becomes cheaper overall. A 4L PCB assembly (core 0.8 mm + 2 × 0.2 mm pre-preg) costs roughly 1.8× double-sided at 1k pcs, but you save on connectors and reduce assembly touches.

One industrial sensor client moved from 4L to 2L by re-routing ground and saved 23% on total BOM. We spotted that in DFM before tape-out. Another IoT gateway team stayed on 2L but switched to ENIG to meet a five-year field-life spec; the US$0.08/in² upcharge was still 30% cheaper than moving to 4L with HASL.

One-Stop PCBA: Why Customers Add Assembly

Same-day kitting is real: we order your parts or use your kit; either way, parts hit the SMT line the afternoon boards come off final test. No extra freight hop, no kitting delay. We hold 10k passives in our Shenzhen VMI and can source your ICs through Arrow or Digi-Key China – whatever gets you the best landed cost.

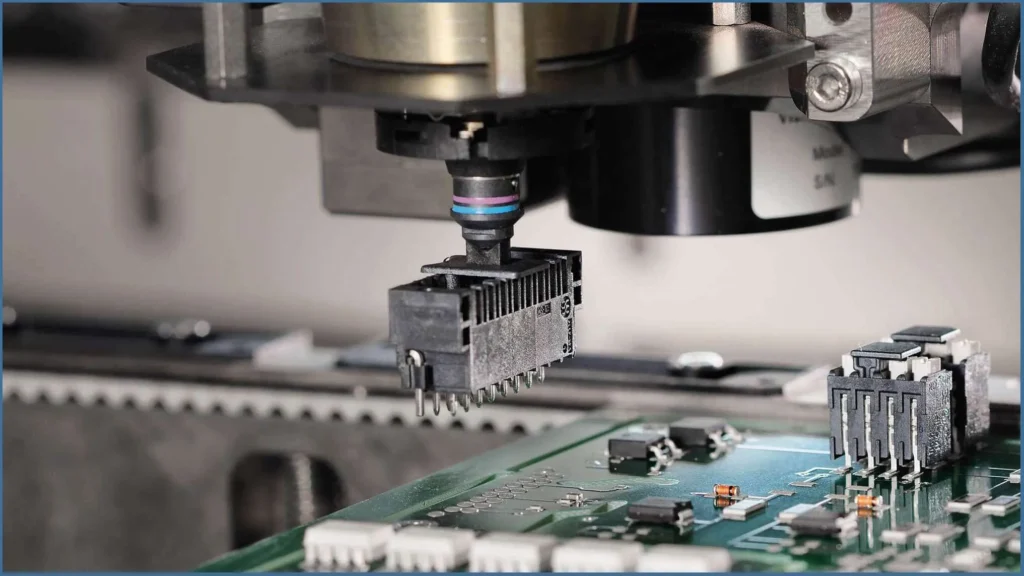

SMT lines run Yamaha i-Cube, 01005 to 0.3 mm pitch BGA, three million cph total. AOI after reflow, X-ray on BGA, ICT, or functional test with your jig. A smart-home controller customer now sends us bare boards and a turnkey BOM; we return programmed, tested assemblies ready for carton pack. It cut their supply chain touches from five to one.

BenChuang Electronics – a Chinese PCB factory that builds, tests, and exports double-sided boards to OEMs worldwide. Contact us today to get a quote.