Wholesale Single-to-Multilayer PCBs: How BenChuang Electronics Helps OEMs Hit Cost & Lead-Time KPIs

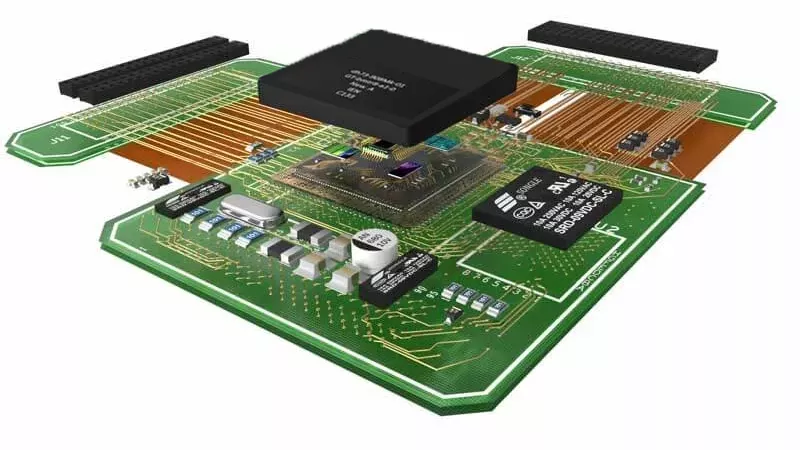

1. Double-Sided PCB – The Work-Horse We Build Most

- Stack-up: FR-4 1.6 mm, 1 oz Cu each side, 0.2 mm min. drill, 0.3 mm min. annular ring

- Surface finish: HASL-LF standard; ENIG or OSP on request – no price shock, we run both baths daily

- Panel size: 580 × 480 mm max.; we route or V-score, your choice

- E-test: flying probe on every panel; 100% AOI before packing

- Standard batch: 5-day build, 3-day DHL; we also keep 1 mm and 0.8 mm cores in stock for 72 h expedited

- Cost tip: leave 10 mm panel border and we can panelise 18-up on one sheet – saves $0.04 per sq. in. on 1,000 pcs

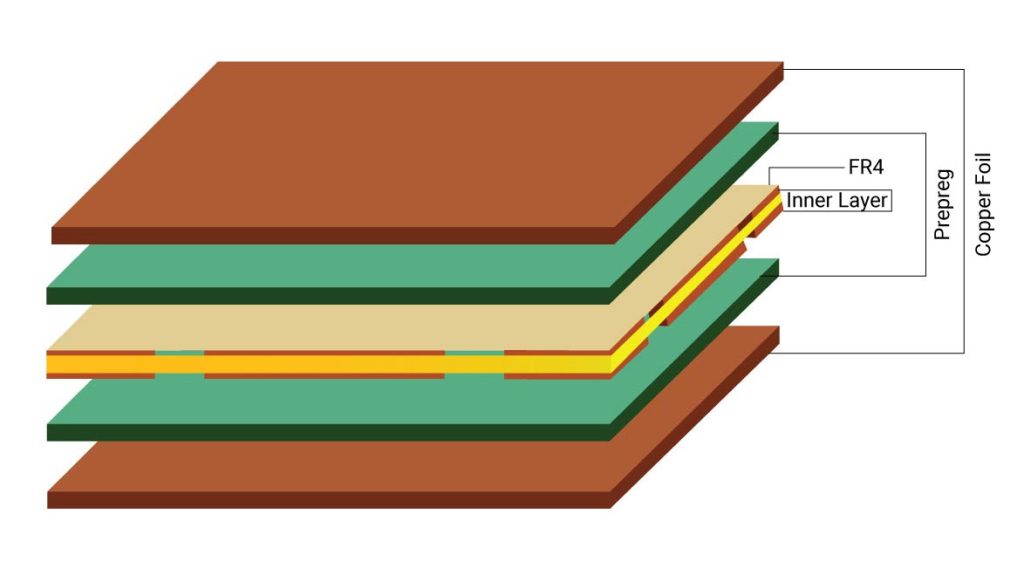

2. 4-Layers – Where Most Cost Worries Start

- Core 0.8 mm + 2 × 0.2 mm pre-preg, total 1.2 mm

- 0.1 mm mechanical drill, 0.15 mm laser if you need via-in-pad

- Plated edge or castellation – no extra lamination cycle, done on the same pass

Price gap: 4L is roughly 1.8 times the double-sided cost in 1,000 units; below 0.1 m², we absorb the lamination setup, so prototypes pay the same multiplier.

Lead-time: 6 days standard, 4 days quick-turn (≤0.4 m² panel area).

Impedance: We etch a 50 Ω coupon on each panel and read it on the Polar CITS, according to your requirements.

3. 6-Layers and 8-Layers – What We Really See in the Quote Queue

- 6L build: 7628 × 3 pre-preg, total 1.6 mm; blind L1-L2 laser via available

- 8L build: 0.1 mm drill, buried via L2-L7, 2.0 mm finished thickness

Cost rule-of-thumb: each extra pair of cores adds ~US$0.06 per sq. in. at 1 k pcs; buried via adds another US$0.03.

Min. slot width: 0.8 mm – we router-cut, no laser router, so keep slots ≥0.8 mm and you avoid a premium.

Lead-time: 7 days (6L), 8 days (8L); quick-turn +2 days.

Copper: outer 1 oz, inner 0.5 oz standard; 2 oz outer is fine, but inner 1 oz pushes lamination cycle to 3 h – we tell you before you commit.

4. Export Logistics We Actually Use Every Week

- FOB Shenzhen (default) – we deliver cartons to Shekou or Yantian terminal, unload once, no cross-dock

- CIF/DDP – we book DHL Express or FedEx International Economy; 3-day door-to-door to the U.S. West Coast, 4-day to the EU

- Paperwork bundle: commercial invoice, packing list, Form A, RoHS statement, UL traceability sheet – according to your requirements

- Palletising: 1 m × 1.2 m Euro pallet, max 500 kg; vacuum + stretch film, silica gel inside

5. One-Stop PCBA Add-On (No Extra Freight Hop)

- Same-day kitting: we order your parts or use your kit; either way, parts hit the SMT line the afternoon boards are laminated

- SMT lines: Yamaha, 01005 to 0.3 mm BGA, 3 million cph total

- AOI after reflow, X-ray on BGA, ICT, or functional test with your test jig

- Conformal coating, burning, packaging – all under one roof; you get one PO, one shipment, one set of docs

6. Typical KPI Shift After Customers Move to BenChuang

| Layer Count | Old Supplier Cost | BenChuang Cost | Days Saved | Annual Volume |

|---|---|---|---|---|

| 2L gateway board | $0.58/in² | $0.44/in² | 6 → 4 days | 30 k |

| 4L motor controller | $0.92/in² | $0.71/in² | 8 → 6 days | 12 k |

| 6L IoT gateway | $1.35/in² | $1.06/in² | 10 → 7 days | 8 k |

Figures taken from 2024 shipment records.

BenChuang Electronics – a Chinese PCB factory that builds, tests, and exports double-sided to multilayer boards every single week. Let us hit your cost and lead-time KPIs on the next PO.