Ways to Increase Circuit Density

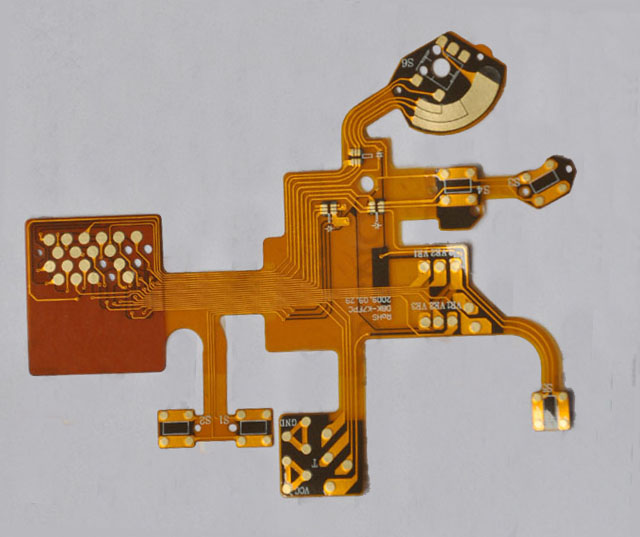

There are three main ways to make printed circuits more compact:

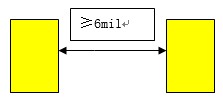

- Make the copper traces and the spaces between them smaller.

- Add more circuit layers to the PCB.

- Shrink the size of vias and pads.

Copper Foil

One clear way to boost circuit performance is by packing more circuitry into the same space. To do this, copper foil technology has seen a lot of improvements over the years. Early on, high-temperature elongation (HTE) foils were developed. Later, we got low-profile foils, very-low-profile foils, thinner foils, and foils designed for high-performance resin systems.

HTE Foil

HTE (often called Class 3) copper foil can stretch more at high temperatures compared to standard copper foils. At around 180 °C, it typically stretches 4–10%. This makes it very useful in multilayer PCBs, because when the board heats up and cools down, the materials expand and put stress on the copper layers and plated holes. Thanks to its ductility, HTE foil reduces the risk of inner-layer cracking and improves connection reliability—especially in thicker boards or those with high resin content, where z-axis expansion is greater.

Low-Profile and Reverse-Treated Copper Foils

Normally, copper foil has two sides: a smooth shiny side and a rough matte side. Traditionally, the rough side was bonded to the PCB material. Reverse-treated foil flips this idea—treatments are applied to the smooth side, which is then laminated to the base.

This change has two major benefits:

- The bonded side is very smooth, which makes it easier to etch fine circuit traces.

- The rougher matte side is now exposed, giving better adhesion for photoresist.

The result? Manufacturers can skip some surface roughening steps, improve imaging, and get better etching yields.

Single-Ply vs. Multi-Ply Constructions

Using a single ply of prepreg is usually cheaper than using multiple plies, although the savings depend on the glass styles and other factors. Performance can also differ:

- Single-ply constructions tend to have lower resin content and offer better control of dielectric thickness. Since there’s only one layer, the thickness variation is statistically smaller than with multiple layers.

- Multi-ply constructions may provide more flexibility in meeting resin or electrical requirements, but with more variation in thickness.

Resin Content

The amount of resin in the laminate matters a lot:

- Lower resin content generally improves reliability because it reduces z-axis expansion. It also helps with dimensional stability, warpage resistance, and dielectric thickness control.

- Higher resin content lowers the dielectric constant, which can improve electrical performance. However, there must be enough resin to properly “wet out” the glass fibers and avoid voids, which is also important for preventing conductive anodic filament (CAF) issues.

In practice, each type of glass style has an optimal resin content range—too little and reliability suffers, too much and you lose stability. The key is finding the right balance.