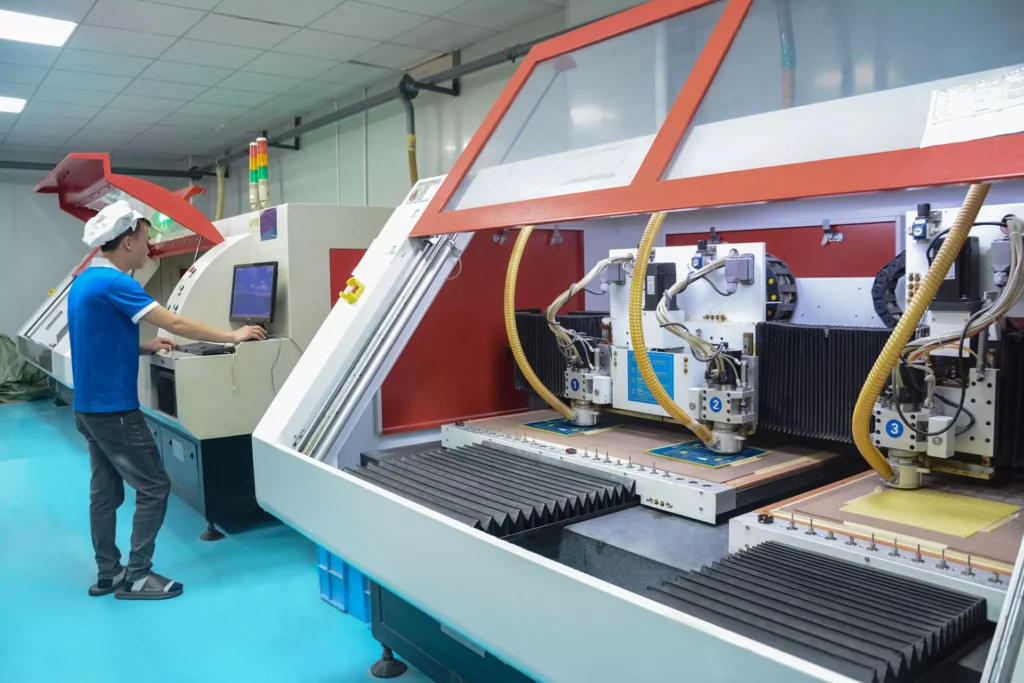

A gong board machine, also known as a PCB gong board machine or PCB curve dividing machine, is a crucial tool in electronic manufacturing. It is specifically designed to accurately segment irregularly shaped PCBs (Printed Circuit Boards) connected by stamp holes. By using milling cutters, the machine cuts PCB boards along pre-programmed paths, ensuring precise segmentation and optimal board quality.

The gong board machine offers several advantages over traditional V-CUT machines, providing higher cutting accuracy and smoother cutting interfaces. Though the operation is more complex, this makes it ideal for processing PCB boards that require intricate and high-precision cuts.

The operation process of a gong board machine typically involves several steps:

- Preparation: Initial setup and inspection of materials.

- Fixing the PCB: Securing the PCB to ensure stability during cutting.

- Importing CAD files: Pre-processing the design files for cutting.

- Drilling and Milling: Precise cutting based on the CAD paths.

- Final Cleaning and Inspection: Ensuring that the cut PCB meets quality standards.

Mastering these operational procedures ensures that the gong board machine can enhance processing efficiency and improve the overall quality of PCB boards. Whether you're working on complex, high-precision designs or need smooth, accurate cuts, the gong board machine is an indispensable tool in PCB manufacturing.