10 Key Questions to Ask When Choosing a China FR4 PCB Manufacturer in 2026 (Green Solder Mask Tips Included)

In the competitive world of electronics manufacturing, selecting the right FR4 PCB manufacturer in China can make or break your project's success. FR4 remains the go-to material for most applications due to its excellent balance of cost, mechanical strength, and electrical performance. And when it comes to solder mask, green is still the industry standard—not just for tradition, but for practical reasons like superior inspection contrast and supply chain reliability.

However, not all manufacturers are created equal. Asking the right questions upfront can help you avoid costly delays, quality issues, and rework. In this guide, we'll cover 10 essential questions to ask potential suppliers, with a special focus on optimizing green solder mask for better yields and reliability.

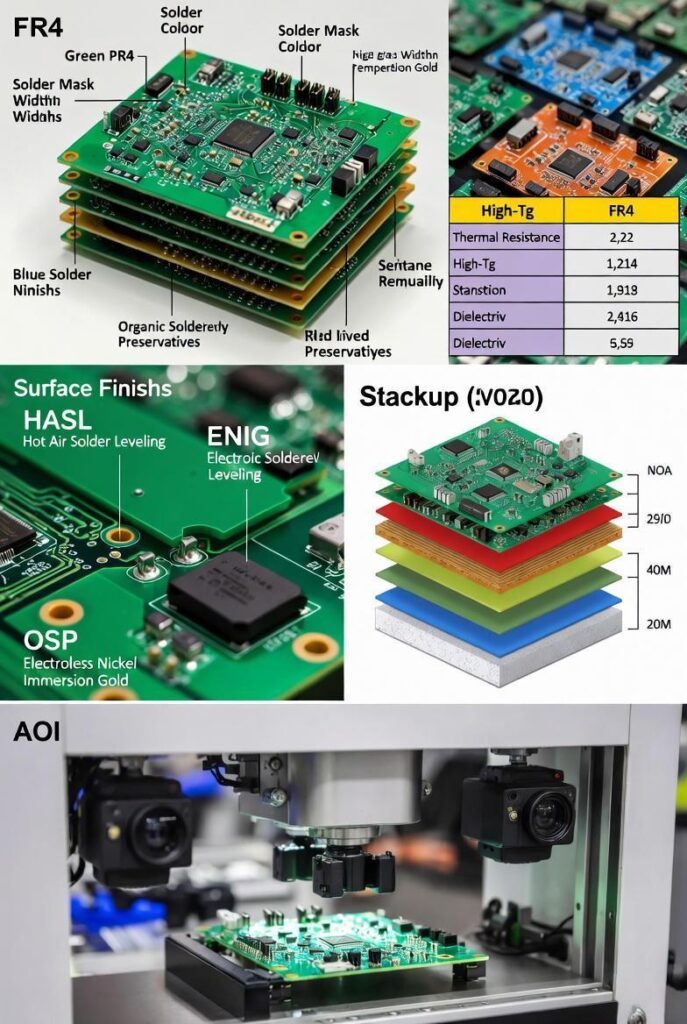

1. What FR4 grades do you offer, and when do you recommend high-TG FR4?

Standard FR4 (Tg ~130-140°C) works for most consumer electronics, but high-TG FR4 (Tg 170°C+) is crucial for power supplies, inverters, or applications with high operating temperatures. A reliable manufacturer should provide DFM (Design for Manufacturability) advice based on your thermal profile to prevent warpage or delamination.

Green solder mask tip: High-TG materials pair well with green mask for consistent curing and adhesion under higher reflow stresses.

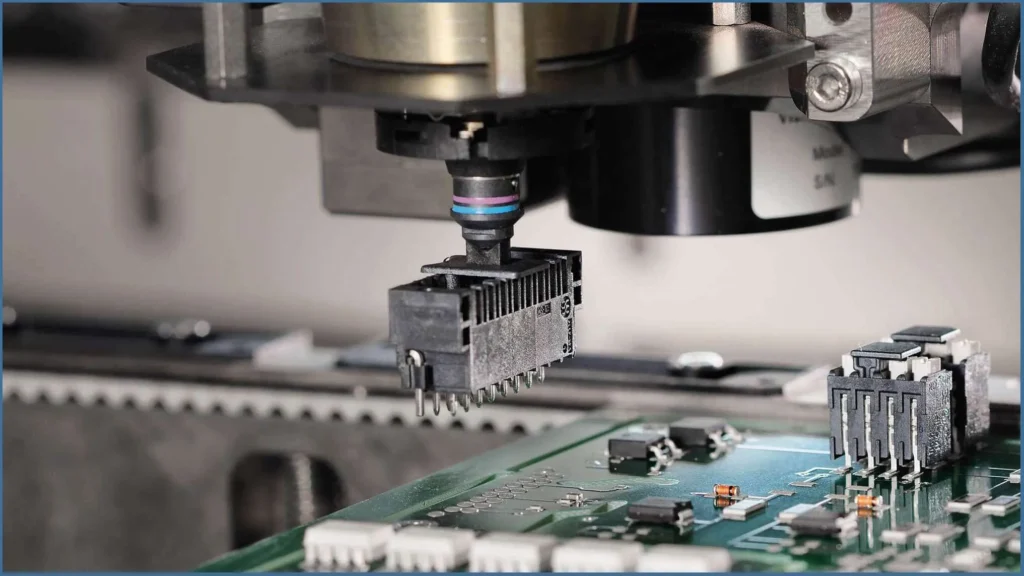

2. How do you ensure consistent quality with green solder mask application?

Green solder mask offers the best contrast for AOI (Automated Optical Inspection) and manual checks, leading to higher yields. Ask about their mask alignment precision, curing processes, and defect rates. Top manufacturers use advanced equipment to achieve tight solder mask clearance and dam accuracy.

Optimization tip: Specify solder mask expansion (typically 0.1-0.15mm) to avoid bridging on fine-pitch components while maintaining coverage.

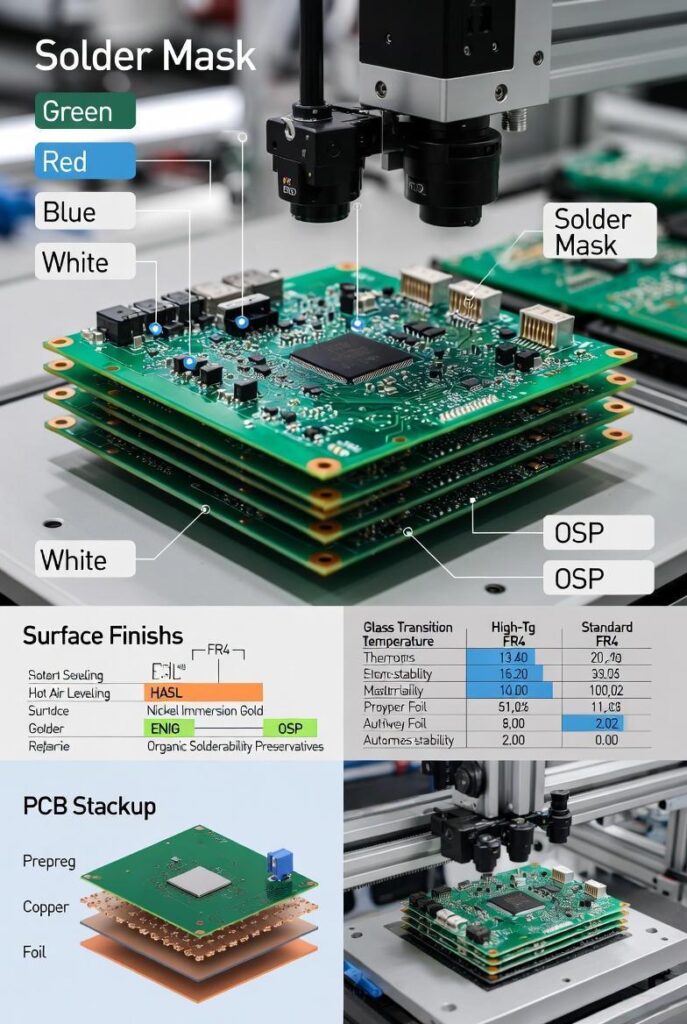

3. What surface finishes do you support, and which is best for green FR4 boards?

Common options include HASL (cost-effective), ENIG (flat for fine-pitch/BGA), and OSP (environmentally friendly). The right choice depends on your assembly process and shelf life needs.

Green solder mask tip: ENIG complements green mask visually and provides excellent solderability, especially for prototypes transitioning to volume production.

4. Do you offer controlled impedance and how do you verify it?

For high-speed designs in communication or embedded systems, impedance control is non-negotiable. Request stackup recommendations and TDR testing reports.

Optimization tip: Green mask's thickness uniformity helps maintain consistent dielectric properties for accurate impedance.

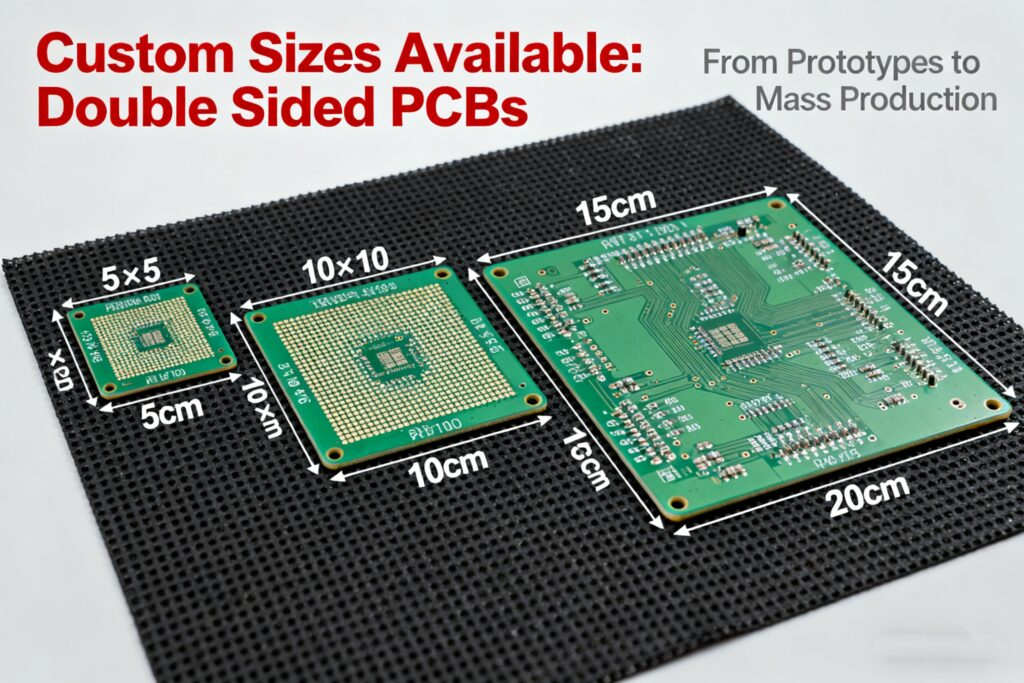

5. What are your capabilities for layer count, thickness, and copper weight?

Most projects use 2-6 layers with 1.6mm thickness and 1oz copper, but confirm support for your specifics (up to 12+ layers, custom thicknesses like 0.8mm or 2.0mm).

6. How do you handle prototypes versus mass production scaling?

Look for manufacturers who maintain material consistency across runs to avoid surprises when scaling. Traceable QC records and electrical testing (flying probe or fixture) are must-haves.

Green solder mask tip: Standardized green mask reduces variables during scale-up, ensuring assembly compatibility.

7. What DFM services do you provide before quoting?

A professional supplier should review your Gerber files for free, suggesting improvements like annular ring sizing, trace/space optimization, or panelization for cost savings.

8. What are your typical lead times and minimum order quantities?

Fast prototypes (7-10 days) and reliable volume delivery are key. Clarify MOQs—good manufacturers support low-volume runs without excessive premiums.

9. Do you comply with IPC standards and provide certifications?

IPC Class 2 or 3 builds, RoHS compliance, and UL listings ensure reliability for industrial or consumer applications.

10. How do you support post-production issues and communication?

Responsive English-speaking support (via email, WhatsApp, or phone) is vital for quick resolutions.

Bonus: Why Green Solder Mask Remains the Top Choice in 2026

Despite trendy colors like black or blue, green solder mask dominates because of its proven benefits: superior AOI contrast, standardized supply chain (faster lead times, lower costs), and higher assembly yields. In our experience, it can improve inspection efficiency by 20-30% compared to darker masks.

At Benchuang Precision Electronics, we specialize in high-quality green FR4 PCBs with full DFM support, high-TG options, and scalable production. Our engineering team reviews every design to optimize for reliability and cost—often catching issues that save clients time and money.

Ready to start your project? Send your Gerber files and specs to William@bcpcbsz.com or WhatsApp +86 17724684094 for a fast quote, free DFM review, and personalized recommendations. We'll help you choose the perfect FR4 configuration, including green solder mask optimizations tailored to your application.

Don't risk your next build—partner with a manufacturer you can trust.